MACHINE SHOP

Heat Exchanger & Pressure Vessel

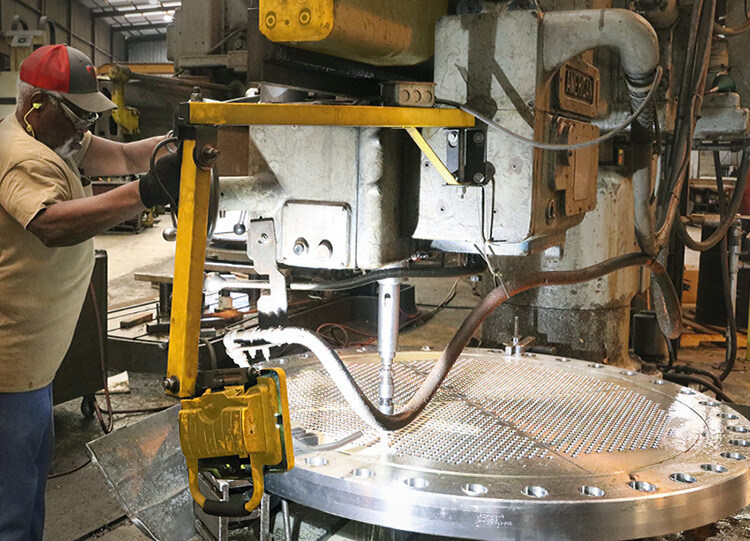

CNC Machining & Drilling

Machining & Drilling Specialist

CNC MACHINING & DRILLING CAPABILITIES AND SERVICES

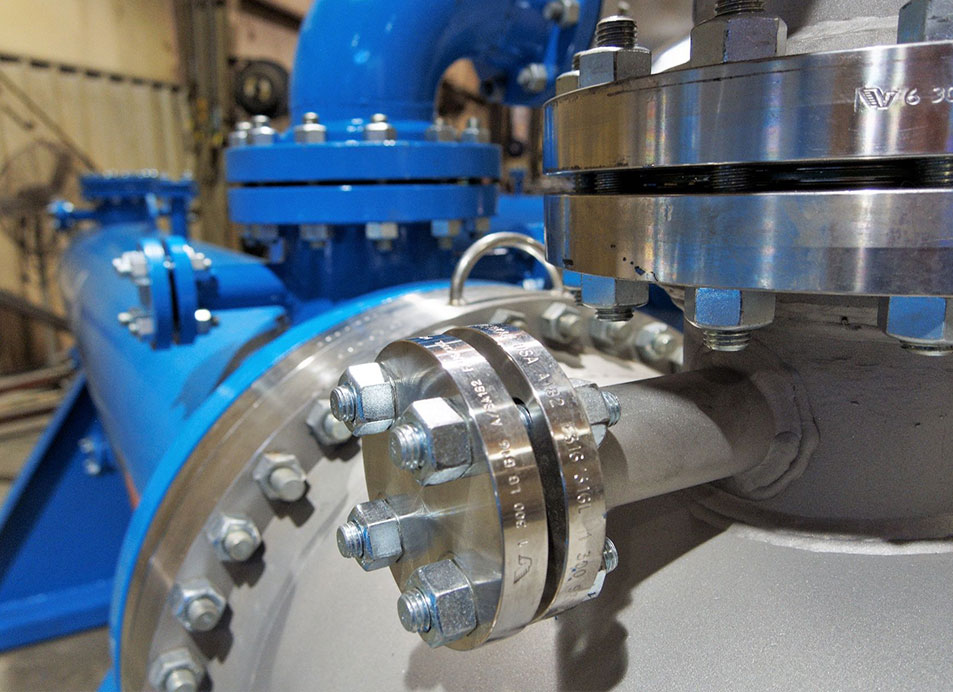

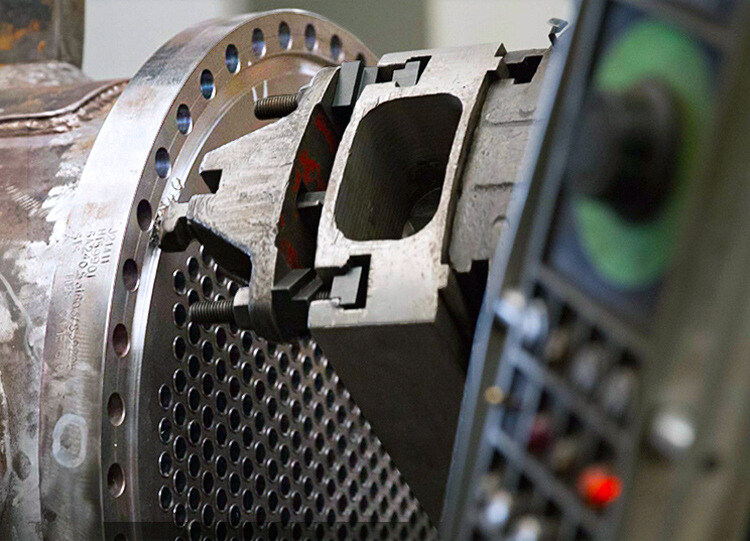

In addition to the fabrication of complete shell and tube heat exchangers and ASME pressure vessels, Metalforms also provides specialized contract drilling and CNC machining services—letting customers benefit from our superior tools and quality for both routine and emergency needs for fabricated parts and components.

With lathes up to 84" in diameter and drills for plate thickness up to 12", our state-of-the-art machine shop supports an extensive range of drilling, milling, ring grooving, and boring applications including turnkey fabrication of all shell & tube heat exchanger and ASME pressure vessel parts and components.

Our 24-7 teams and extensive shop capacity make Metalforms your ideal partner to help prevent and reduce downtime when you experience unexpected, emergency machining & drilling needs.

Our ability to deliver to urgent schedules for parts and components has proven invaluable to many of our customers during both planned turnarounds—and unplanned outages.

CONTACT US

Call us today to speak with one of our machine shop specialists at: 409-842-1626 or click to contact us below:

SPECIALIZED SERVICES SHOPS

Heat Exchanger

Fabrication Services

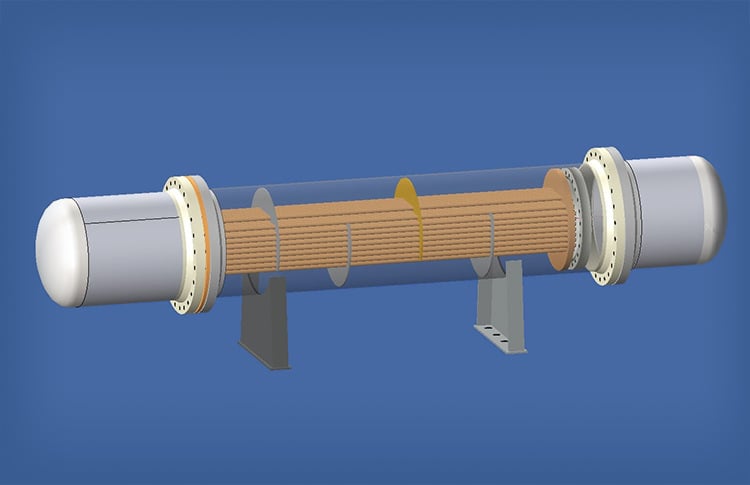

Metalforms is an industry leader in the design and fabrication of shell & tube heat exchangers for midstream oil & gas, refining, petrochemical, specialty chemical, and other process industries.

With 24/7 fabrication teams—and parallel, multi-track, project execution capabilities—we support all your project project needs—from greenfield projects to plant turnarounds, overhauls, debottlenecking, modifications, and upgrades—as well as urgent, emergency heat exchanger replacement.

Heat Exchanger

Machining & Drilling

Our specialized contract drilling and CNC machining services let our customers enjoy all the benefits of our superior tools and quality for both routine—and emergency—fabricated parts and components for shell & tube heat exchangers and ASME pressure vessels.

With 24-7 teams and extensive shop capacity, Metalforms is your ideal partner to help prevent and reduce downtime for all your planned turnarounds—and unplanned outages.

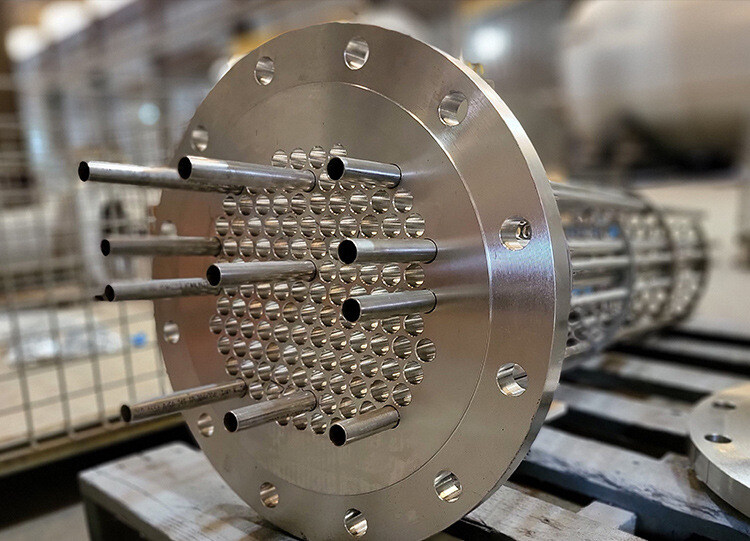

Full Service Heat Exchanger

Tube Bundle Fabrication

Our Bundle Shop produces the highest quality shell & tube heat exchanger tube bundles and air cooler (ACHEs) tube bundles for newly fabricated heat exchangers, replacement, or repair.

In addition to the assembly of new tube bundle units, the Shop performs expert bundle repairs—including complete strip and retube services for both TEMA type heat exchangers and ACHEs.

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

HEAT EXCHANGERS EXPERTISE

-

Your One-Stop Heat Exchanger Headquarters

With the highest quality in-house precision-machining, welding and assembly capabilities, we deliver custom and turnkey fabricated heat exchanger and ASME pressure vessel parts and components for the most demanding applications and environments—consistently achieving industry-leading performance and reliability.

No matter what your requirements may be, Metalforms has the solution.

Together with our 24-7 Bundle Shop and 24-7 Fabrication Shop, our teams are standing by for all your most urgent heat exchanger related needs.

-

Machine Shop Capabilities

Our machine shop resources include and extensive range of cutting-edge machinery and equipment including CNC and manual machines, welding equipment, and overhead cranes. A few highlights of our fixed assets include:

• Multiple Horizontal Boring Mills

• Multiple Large Capacity Drilling & Milling Machines

• Multiple Vertical Turret Lathes

• Multiple overhead bridge cranes

• Portable flange facing system

• Radial Drill

• Roll plate bending machine

• Straightening press

• CNC lathe for producing tube plugs

• Jet toolroom engine lathe

• Highly qualified, trained, and certified machinists

-

Example Projects

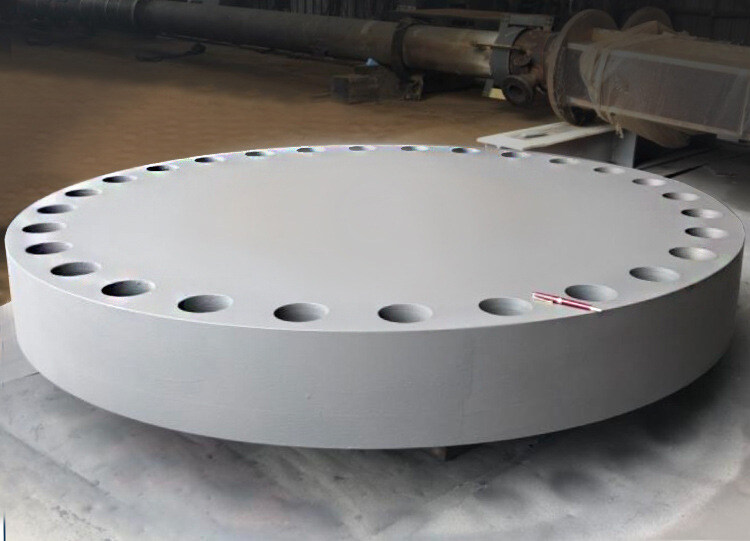

From tubesheets, to baffles, flanges and broad array of other miscellaneous items, our experienced machine shop professionals can deliver the parts and components you need - on time, every time, inclulding:

- Tubesheets

- Clad tube sheets

- Baffles

- Flanges

- Partition Plates

- Support plates

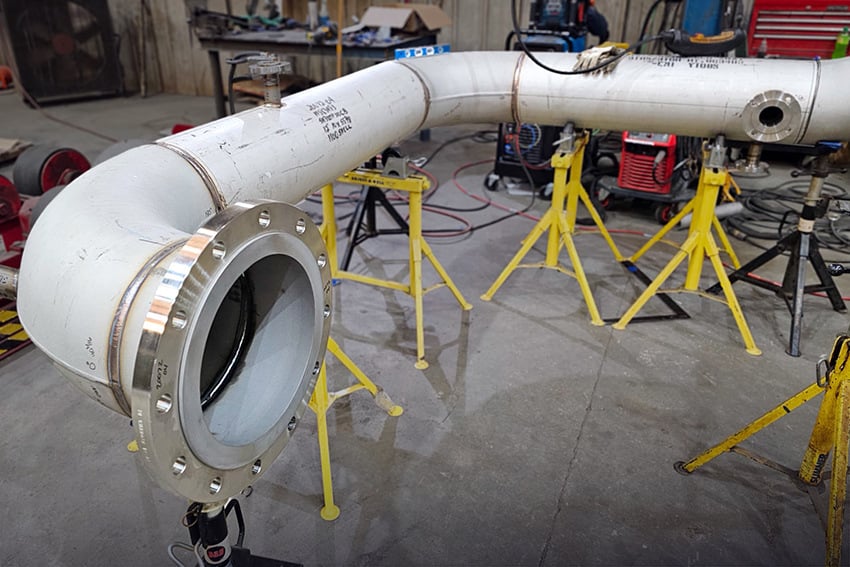

- Connections/ Inlets/Outlets

- Installation

Mountings, Saddles

- End Caps

- Channel Covers

- Vents

- Valves

- Lift Lugs

Tube Bundles - Plain, Longitudinally Finned, and Studded

-

Certifications

We are committed to delivering the highest-quality shell and tube heat exchanger and asme pressure vessel parts and components to individual customer specifications—and the following industry standards:

• TEMA Class R, C & B

• ASME U, U2, U3, and S Certifications

• NBIC Certification

• API 660

• Licensed fabricator of Phillips Petroleum

Rod Baffle Bundles

-

MetallurgyWe work with an extensive array of metallurgies to serve virtually any heat exchanger or asme pressure vessel application need—as well as other customer-specified materials—including:

• Carbon Steel

• Low Alloy Steel

• Austenitic Stainless Steel

• Ferritic Stainless Steel

• Duplex Stainless Steel

• Titanium

• Copper Nickel1 ¼

• Chrome• Hastelloy

• Inconel

• Monel

• Nickel

• Brass

• Explosive Bond Cladded Materials

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only