Heat Exchanger

Fabrication

End-to-End Solutions:

FABRICATION, INSTALLATION

MAINTENANCE, REPAIR

Engineering

Capabilities

Shell & Tube Heat Exchangers,

ASME Pressure Vessels, Process Piping

DESIGN, ENGINEERING, RE-RATING

Heat Exchanger

Tube Bundles

24-7 TUBE BUNDLE REPAIR

& REPLACEMENT for Shell & Tube

Heat Exchangers & Air Coolers

Heat Exchanger

Strip & Retube

24-7 STRIP & RETUBE SERVICES

for Shell & Tube Heat Exchangers

& Air Coolers (ACHE's)

Advanced Heat

Transfer Solutions

HAIRPIN/Double Pipe & Multitube

Heat Exchangers, TANK HEATERS,

TWISTED TUBE Technology

Heat Exchanger

Parts

Shell & Tube Heat Exchangers

& Pressure Vessels REPLACEMENT

COMPONENTS & PARTS

Asme Pressure

Vessel Fabrication

Custom ASME Pressure Vessel

ENGINEERING, FABRICATION,

MODIFICATION, & REPAIR

Heat Exchanger

Re-Rating

Shell & Tube Heat Exchangers &

ASME Pressure Vessels

RE-RATE & MODIFICATION

Heat Exchanger Solutions & Services Specialist

Innovative Solutions for High Performance & Efficiency

HEAT EXCHANGERS & ASME PRESSURE VESSELS

ENGINEERING • FABRICATION • REPAIR

We specialize in the delivery of custom engineered and fabricated Shell & Tube Heat Exchangers, ASME Pressure Vessels, Process Piping and other equipment, serving customers in midstream oil & gas, refining, petrochemical, specialty chemical, and other industries.

We support our customers with an array of related services including engineering, fabrication, test, repair, maintenance, re-rating, modification, and other services—including 24-7 emergency repair.

As part of the TransTech family of companies we can offer an extensive range of fabrication solutions, field services, and 24/7 support services—including fabrication of large process vessels and process piping for our chemical and industrial clients—while leveraging fabrication assets and field services capabilities from locations across the U.S.

CONTACT US

Contact us today to speak with one of our solutions professionals at 409-842-1626 or click to contact us below:

WORK WITH METALFORMS

HEAT EXCHANGER SERVICES

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

WHERE ENGINEERING MEETS FABRICATION

Specialized Services Spotlight

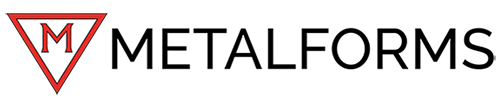

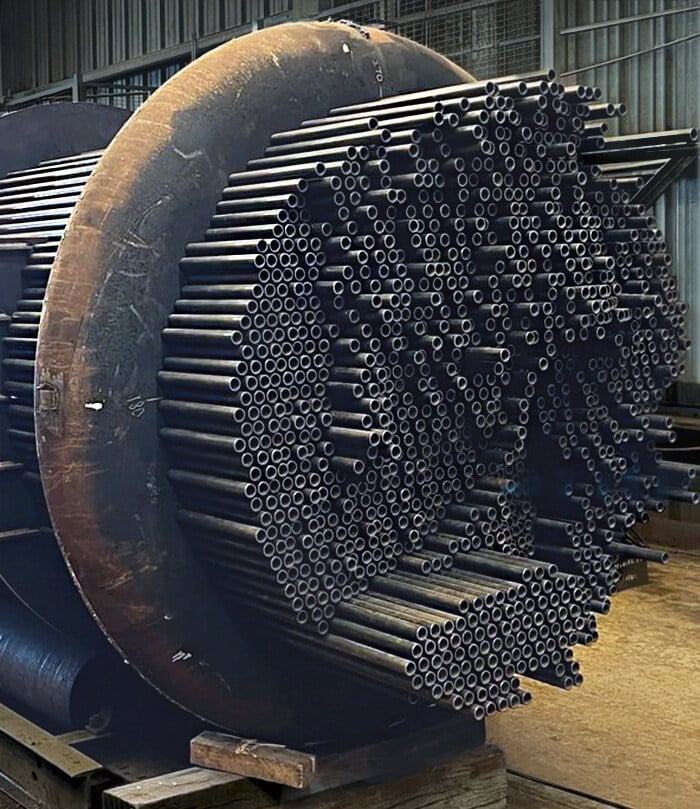

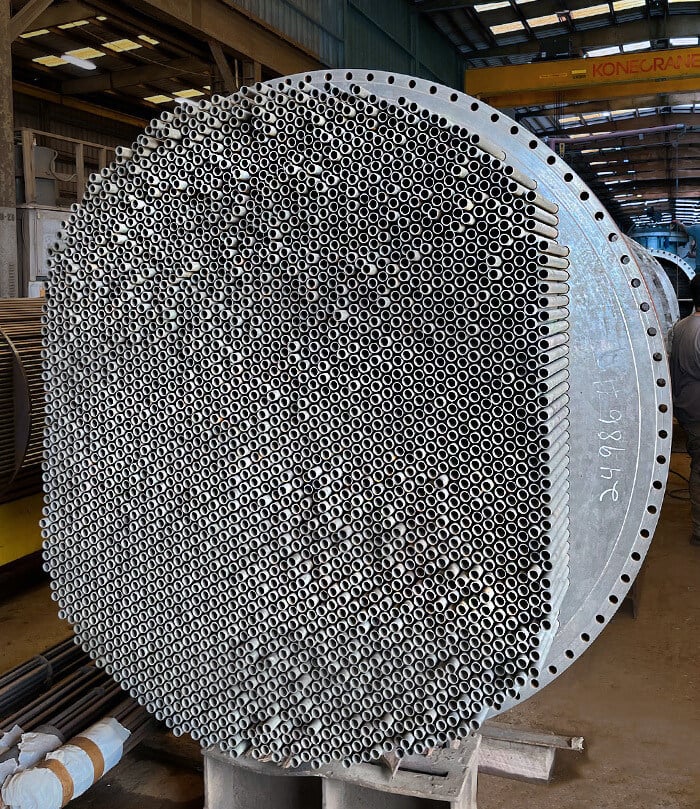

New Shell & Tube Heat Exchanger Fabrication

Metalforms is an industry leader in the design and fabrication of shell and tube heat exchangers, built to TEMA and ASME standards.

With 24/7 fabrication teams, and parallel project execution capabilities, we support all your greenfield and brownfield project heat exchanger needs–including new facilities, plant overhauls, modifications, and upgrades–as well as urgent expedited and emergency heat exchanger replacement.

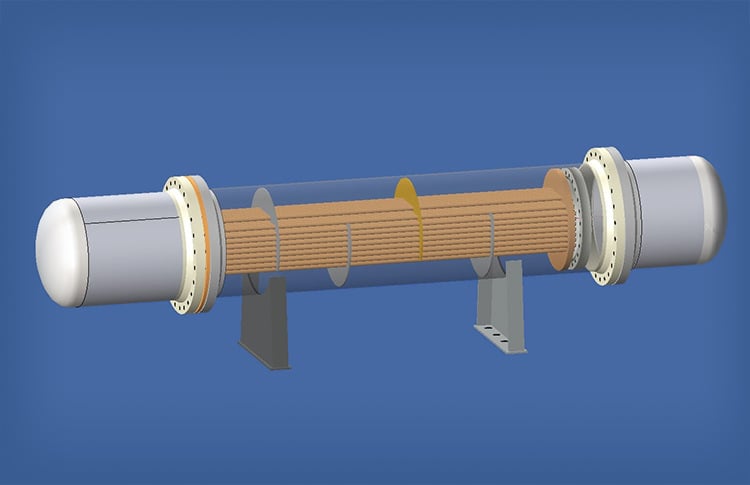

Specialized Services Spotlight

24-7 Heat Exchanger

Repair Services

Metalforms delivers the most comprehensive shell & tube heat exchanger repair services you’ll find—from gasket surface repair, weld repairs, and re-machining to component replacement, re-tubing, material upgrades, re-rating, and more—all under one roof. One point of contact. One invoice.

With 24-7 service teams, and parallel track, multi-project execution capabilities, we have the expertise, capabilities, and skills needed to get your plant back online—fast.!

Specialized Services Spotlight

EXPEDITED TUBE BUNDLE REPLACEMENT

We deliver expert shell & tube heat exchanger tube bundles and air cooler (ACHEs) tube bundles for newly fabricated heat exchangers, replacement, or repair, supporting a broad range of midstream oil & gas, refining, petrochemical, and specialty chemical applications—and more.

With 24-7 teams and multi-track, parallel project execution capabilities, we support all your routine and emergency needs.

Specialized Services Spotlight

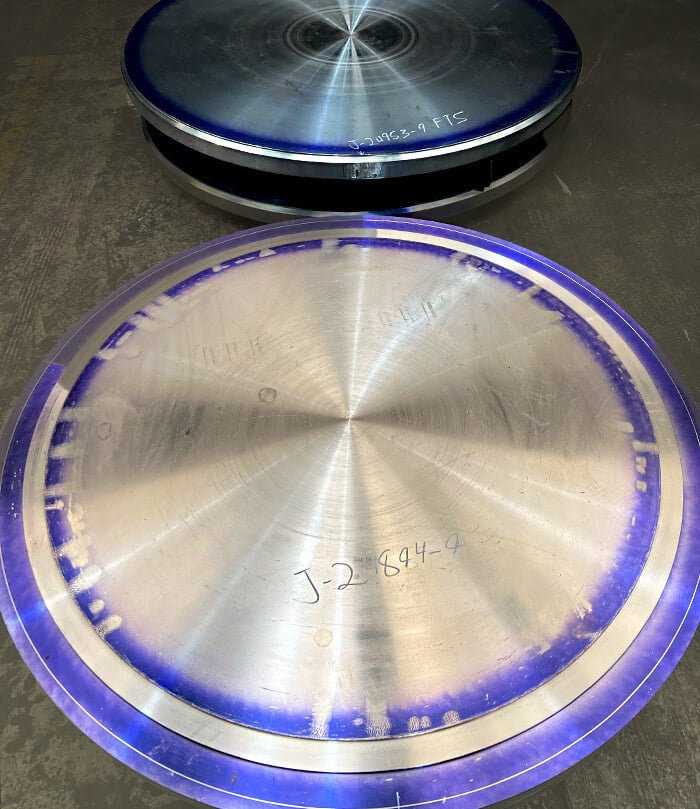

Heat Exchanger Parts

Metalforms can replace all parts and components for shell & tube heat exchangers with your choice of identical or modified newly manufactured, replacement items.

Replacing key components can restore the performance of a unit that has lost efficiency—and can be a cost-effective way to both ensure optimal performance and prolong the life of your heat transfer equipment.

Specialized Services Spotlight

ACHE TUBE BUNDLE REPAIR & REPLACEMENT

Metalforms delivers custom fabricated Air Cooled Heat Exchanger (ACHE) and fin fan type heat exchanger tube bundles for a broad range of applications for our customers across midstream oil & gas, refining, petrochemical, and chemical industries—and others.

With 24-7 teams and parallel track, multi-project execution capabilities, we support all your routine and emergency needs.

Specialized Services Spotlight

ASME Pressure Vessel Fabrication

Metalforms is an industry leader in the custom design and fabrication of ASME pressure vessels.

Our skilled fabrication teams manufacture pressure vessels in a wide variety of sizes and materials to meet the unique requirements of your application—and our expert, in-house engineers possess the knowledge and expertise to conduct detailed mechanical evaluations, ensuring your new pressure vessel is tailored to your specific needs.

Specialized Services Spotlight

Heavy Hauling, Delivery & Installation

From providing expert engineering assistance and fabrication to coordination freight and offloading, tank set, installation, and equipment integration, Metalforms can provide a complete, turnkey solution.

Ordering new and replacement vessels, tanks, and equipment has never been easier!

PROVEN PERFORMANCE BY DESIGN

INNOVATION WITHOUT LIMITS

Optimal Heat Exchanger Solutions for Every Application

For critical applications from oil & gas processing, to process manufacturing, to air separation—including cryogenic systems—we deliver a comprehensive range of heat exchangers to serve every need

Fixed Tube Sheet

- Maximum heat transfer

- Simple construction

- Economical solution

Floating Tube Sheet

- Tube bundle can expand freely

- Supports differential thermal expansion between shell & tubes

U-Tube

- U-tubes can readily expand or contract as needed

- Only one U-tube is required, hence lower cost

BAHX

- Brazed aluminum heat exchanger (BAHX) installation, maintenance, repair

- Cryogenic piping

Replacement Tube Bundles

- U-tubes can readily expand or contract as needed

- Only one U-tube is required, hence lower cost

Air Cooler Bundles

- Air cooler bundle fabrication

- Bundle repair & retubing

- Frame repair

Hairpins/Double-pipe

- Efficient performance, proven reliability in a compact footprint

- Simple design supports ease of cleaning, maintenance–and lower operational costs

Hairpins/Multi-tube

- Delivers exceptionally high efficieny & reliability

- Greater surface area supports high heat-transfer rates

- Uniform fluid flow supports enhanced thermal performance

What Makes Us Different?

-

End-to-End SolutionsUnlike many of our competitors, Metalforms performs virtually all engineering, design, fabrication, test, modification, and repair activities in-house, enhancing our control over quality and schedules—and accelerating project delivery.

Our teams of experienced engineering and fabrication professionals consistently deliver high-quality products for both routine and urgent needs—to committed timelines.

But it doesn't end there, we also offer heavy hauling and logistics coordination for all heat exchangers, vessels and equipment—including managing all required transportation permits.

-

24-7 Emergency RepairWhether you have a planned—or unplanned—shutdown, time equals money.

Metalforms has the capacity and capabilities to diagnose and solve your routine and urgent shell & tube heat exchanger and asme pressure vessel issues, to help you get your plant back online with unmatched speed—including around-the-clock fabrication teams supporting 24-7 emergency repairs.

Learn more about our 24-7 repair services here.

-

Parallel-Track, Multi-Project ExecutionOur parallel-track work processes enable simultaneous, multi-project job execution—supporting faster repair of your in-service shell & tube heat exchangers as well as faster new unit fabrication—supporting streamlined, more efficient workflows for our customers.

Whether you have a planned—or unplanned—shutdown, Metalforms will help you get your plant back online—fast—reducing downtime and increasing production.

-

In-House NDE

Our in-house quality control (QC) capabilities include non-destructive examination (NDE)

Our highly trained and qualified teams apply cutting-edge NDE methods to inspect all newly fabricated heat exchangers, pressure vessels, and other equipment, as well as to diagnose issues with in-service and used equipment to enhance quality control—and support faster turnaround times, by eliminating the need to outsource testing services.

In-house NDT allows for immediate inspection and identification of any material defects or fabrication flaws, ensuring that only high-quality components are used and any identified flaws can be addressed—and reducing the risk of failures and extends the lifespan of all our fabricated products.

-

Locations Across the U.S.As part of the TransTech family of companies, we offer an extensive range of fabrication solutions, field services, and 24/7 support services—including fabrication of large process vessels and process piping for our chemical and industrial clients—while leveraging fabrication assets and field services capabilities from locations across the U.S.

View all our locations here.

Download the TransTech Corporate Flip Book to Learn More:

CTA

Our Company

CAREERS

Join a team that is continually breaking new ground and pushing boundaries in engineering construction, installation, operations and maintenance - delivering solutions to our customers across all phases of the plant & facility lifecycle.

HSE

We perform our work to the highest safety standards with a goal zero approach: zero incidents, zero accidents, and zero environmental releases.

MISSION & VALUES

We define our success by the way we impact the lives of the people around us: