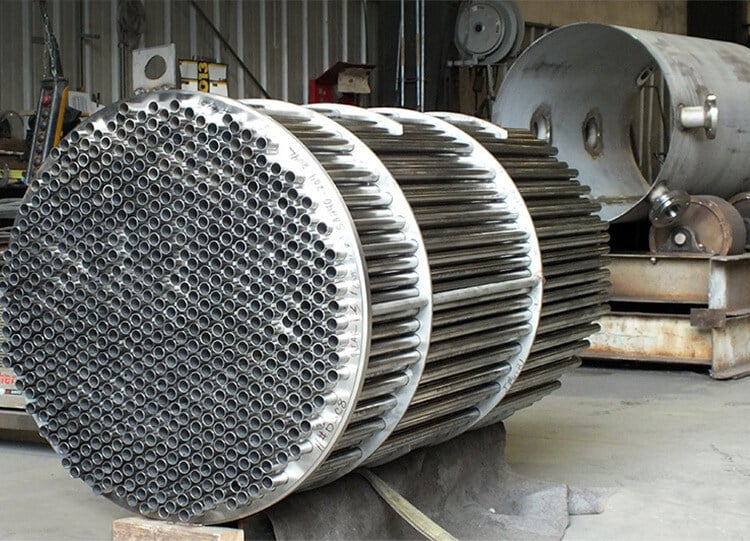

STRIP & RETUBE

Shell & Tube Heat Exchanger & ACHE

Strip & Retubing Services

Heat Exchanger Strip & Retube

HEAT EXCHANGER STRIP & RETUBE SERVICES

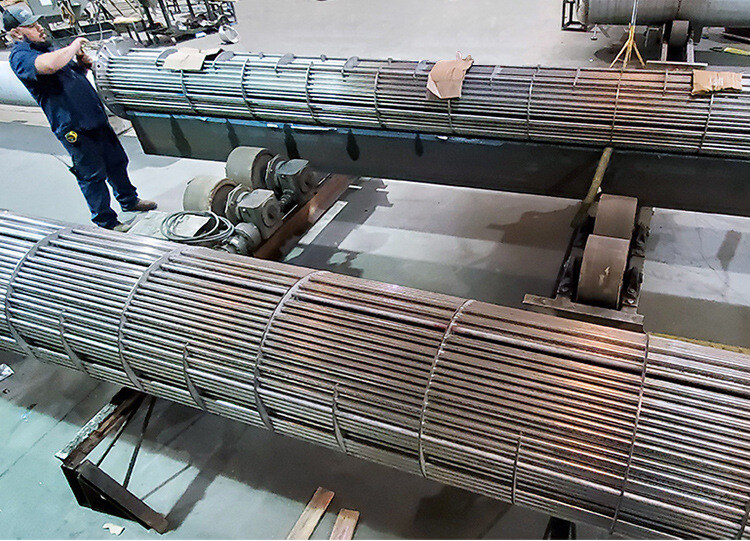

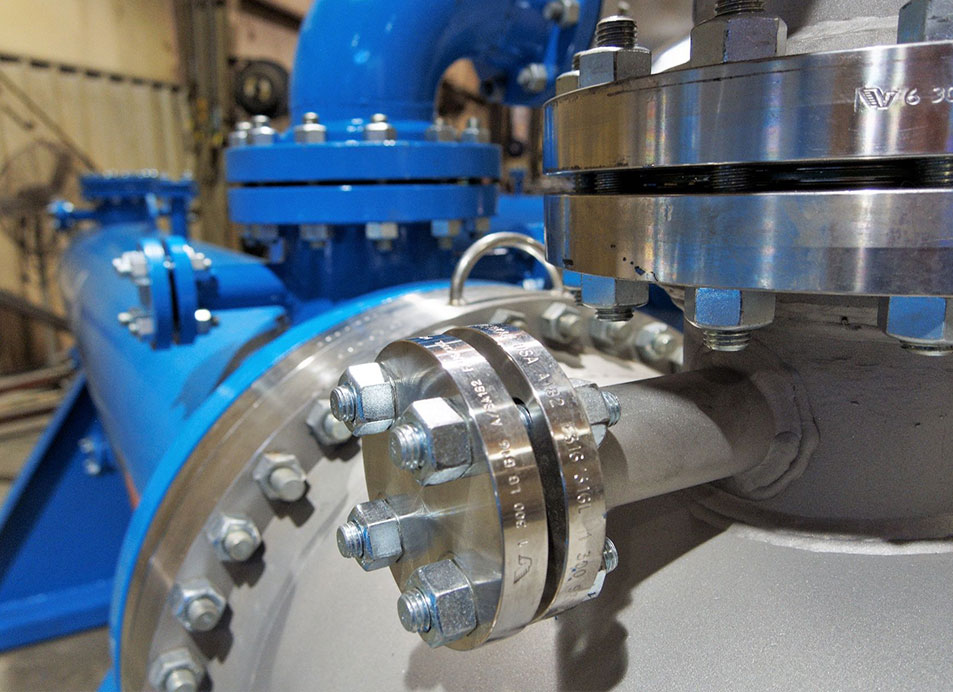

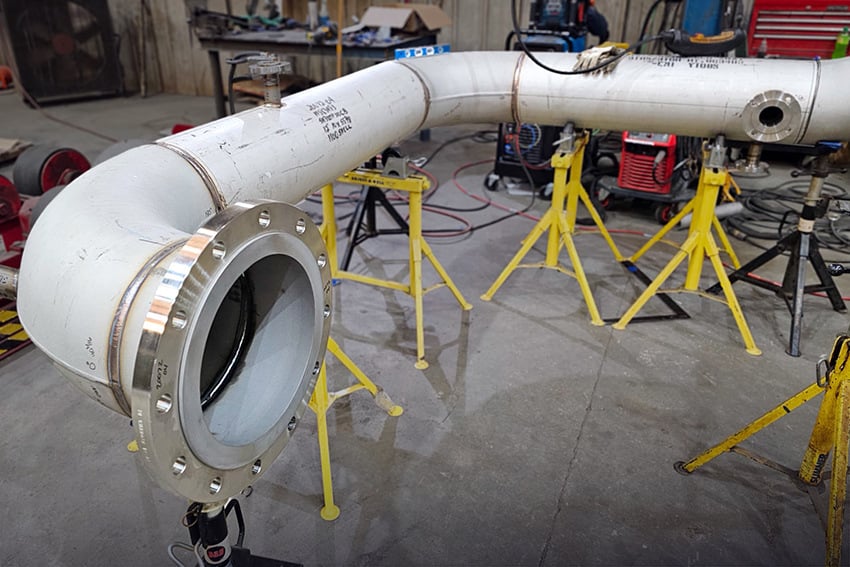

We deliver expert strip and retubing services for all types of shell & tube heat exchangers as well as TEMA, ASME, or API air cooled heat exchangers (ACHEs). Our seasoned teams can strip and retube your heat exchanger in a fraction of the time it takes to build a new unit, to get your plant back online—fast.

In many cases, this approach is preferred to unit replacement for both efficiency and speed—but also for its lower cost. In some cases, such as an older heat exchanger with a history of maintenance issues, replacement can be the more cost-effective approach in the long run.

Our own in-house team of highly-trained quality control inspectors, engineering, and fabrication specialists will conduct a thorough inspection of your heat exchanger. We’ll provide you with all your options and advise on your best course of action—including any necessary repairs or potential upgrades to enhance performance, efficiency, and/or longevity.

Metalforms has the unique ability to handle multiple strip and retube jobs simultaneously—and with our ability to perform work around the clock, 24/7, we can meet your most demanding project needs!

|

|

|

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

HEAT EXCHANGERS EXPERTISE

-

Our ProcessOnce a unit arrives in our shop, it will be rapidly disassembled, and inspected by our highly trained in-house quality inspectors to assess required work—and identify any potential needed repairs. The discovery of unforeseen issues can often save our clients significant time and expense by preventing unexpected future downtime.

We'll contact you to review all our findings—and discuss with you all needed work, potential repairs, or other recommendations. Our team will then proceed according to the agreed plan of action.

Whether you need a partial or full retube, repairs, or any desired upgrades, our retubing specialists work 24-7 to perform all necessary work to return your heat exchanger to service—fast!

-

Metallurgy

We can retube your heat exchanger in accordance with virtually any metallurgy requirements, including an extensive array of readily available materials:

• Carbon Steel

• Low Alloy Steel

• Austenitic Stainless Steel

• Ferritic Stainless Steel

• Duplex Stainless Steel

• Titanium

• Copper Nickel1 ¼

• Chrome• Hastelloy

• Inconel

• Monel

• Nickel

• Brass

• Explosive Bond Cladded Materials

• More

-

Fixed Tube Sheet Heat ExchangersIn a fixed tube sheet heat exchanger, the tube bundle can't be removed as the shell and tube sheets are welded together. Because of this, we completely disassemble these units before proceeding with our work.

Following abrasive blasting of the shell interior and baffle assembly—to remove scale or other deposits that may have built up over time—we perform a thorough inspection of the shell, baffles, and other parts to detect any damage or wear such as cracks or pitting, that may not be visible when covered with deposits. Ensuring all parts are clean and in good condition helps ensure optimal performance, efficiency, and uptime of your unit.

We'll review all findings with you prior to making any needed repairs.

-

Floating Head Heat Exchangers

The design of a floating head heat exchanger enables the entire tube bundle to be readily removed as a single unit, which streamlines the stripping process.

While easier tube access makes the retubing process more efficient than a fixed tube heat exchanger for example, our overall process is similar. If needed, abrasive blast is used as part of the cleaning process, to remove any corrosion or other build-up prior to our comprehensive inspection. Identifying and repairing any defects ensures optimal performance, uptime—and longevity—of your unit.

We'll review all findings with you prior to beginning work and if any needed repairs are identified.

-

Hairpin Heat Exchangers

Hairpin heat exchangers—characterized by either a U-shaped or straight configuration of concentric tubes—generally have a simpler design which eases the stripping process.

Our overall process of inspection is similar to other heat exchanger types, and begins with disassembly and cleaning. Abrasive blast will be used to remove fouling, scale and other buildup if necessary after which we perform our thorough inspection. Detecting damage that may be hidden beneath deposits—and repairing any defects discovered—helps ensure optimal performance, uptime, and long life of your unit.After our inspection is complete, we'll review all findings with you prior to performing any needed repairs.

-

U-tube Heat Exchangers

The stripping process is somewhat more complex for u-tube heat exchangers, due to the shape of the tubes, which must be carefully removed to avoid damage to the u-bends.

As with other heat exchangers, our cleaning process includes abrasive blast as needed to remove any fouling and scale from the tubes—and facilitate our thorough inspection. We pay particular attention to baffles, which provide crucial support to the tubes and are essential for preventing potential sagging or vibration and ensuring optimal operation, performance—and uptime—of your heat exchanger.

Once our inspection is complete, we'll review all findings with you before proceeding with any needed repairs.

-

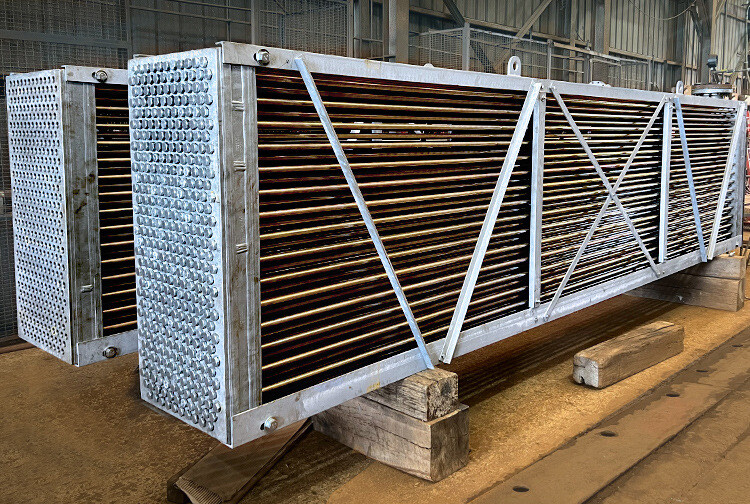

Air Cooled Heat ExchangersOur expert teams can strip and retube all TEMA, ASME, or API air cooled heat exchangers (ACHEs).

ACHEs follow a retubing process that is similar to other heat exchangers. That said, ACHE's used in refineries and oil and gas processing plants are more likely to have finned tubes, which can make the stripping process a bit more complex. Finned tube surfaces need to be handled with additional care and attention to avoid damage.

As with all shell and tube heat exchangers, cleaning is the first step and abrasive blast is used as needed to remove any fouling or scale from the tubes, prior to our inspection. Once our inspection is complete, we'll review all findings with you before proceeding with any additional needed repairs.

Retubing air coolers with finned tubes requires specialized skills and techniques to maintain the integrity of the fins during the installation process. Our seasoned teams have the expertise and equipment to ensure your ACHE's are retubed to the highest standards and comply with all related codes and regulations—to deliver optimal performance and uptime for your plant.

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only

ACHIEVE PEAK PLANT PERFORMANCE

SPECIALIZED SERVICES SHOPS

Heat Exchanger

Fabrication Services

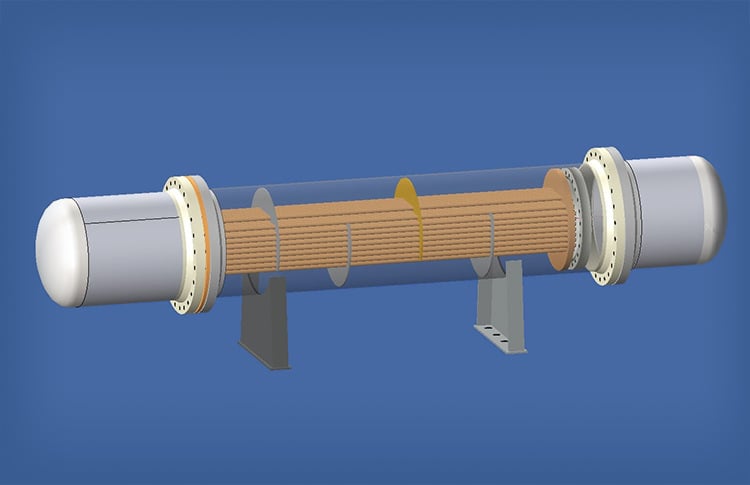

Metalforms is an industry leader in the design and fabrication of shell & tube heat exchangers for midstream oil & gas, refining, petrochemical, specialty chemical, and other process industries.

With 24/7 fabrication teams—and parallel, multi-track, project execution capabilities—we support all your project project needs—from greenfield projects to plant turnarounds, overhauls, debottlenecking, modifications, and upgrades—as well as urgent, emergency heat exchanger replacement.

Heat Exchanger

Machining & Drilling

Our specialized contract drilling and CNC machining services let our customers enjoy all the benefits of our superior tools and quality for both routine—and emergency—fabricated parts and components for shell & tube heat exchangers and ASME pressure vessels.

With 24-7 teams and extensive shop capacity, Metalforms is your ideal partner to help prevent and reduce downtime for all your planned turnarounds—and unplanned outages.

Full Service Heat Exchanger

Tube Bundle Fabrication

Our Bundle Shop produces the highest quality shell & tube heat exchanger tube bundles and air cooler (ACHEs) tube bundles for newly fabricated heat exchangers, replacement, or repair.

In addition to the assembly of new tube bundle units, the Shop performs expert bundle repairs—including complete strip and retube services for both TEMA type heat exchangers and ACHEs.

%20(1).jpg)

-1.jpeg)

.jpg)