THERMAL DESIGN ENGINEERING

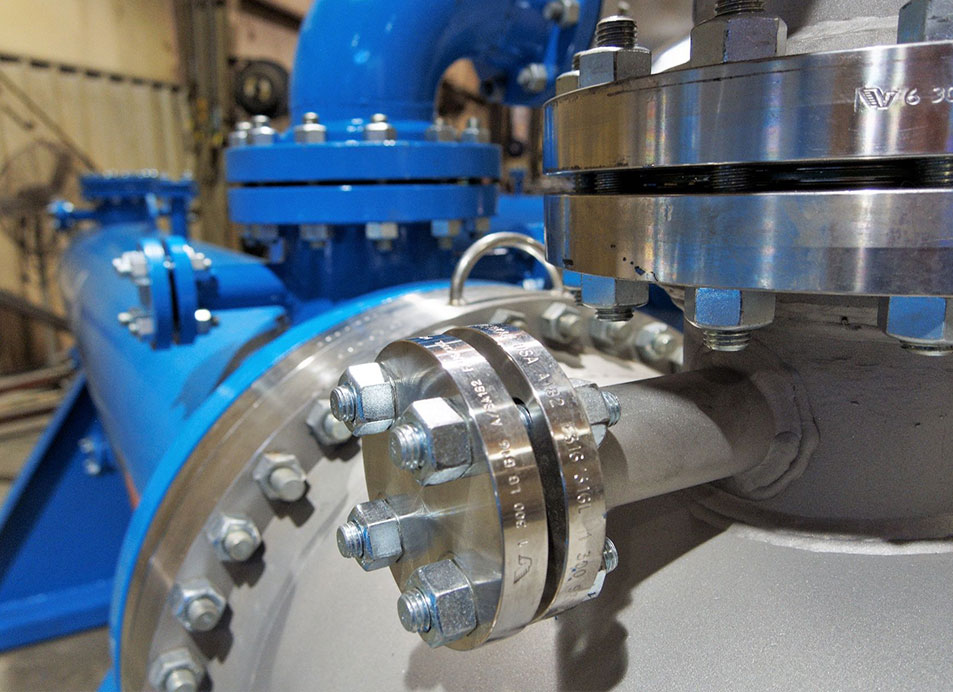

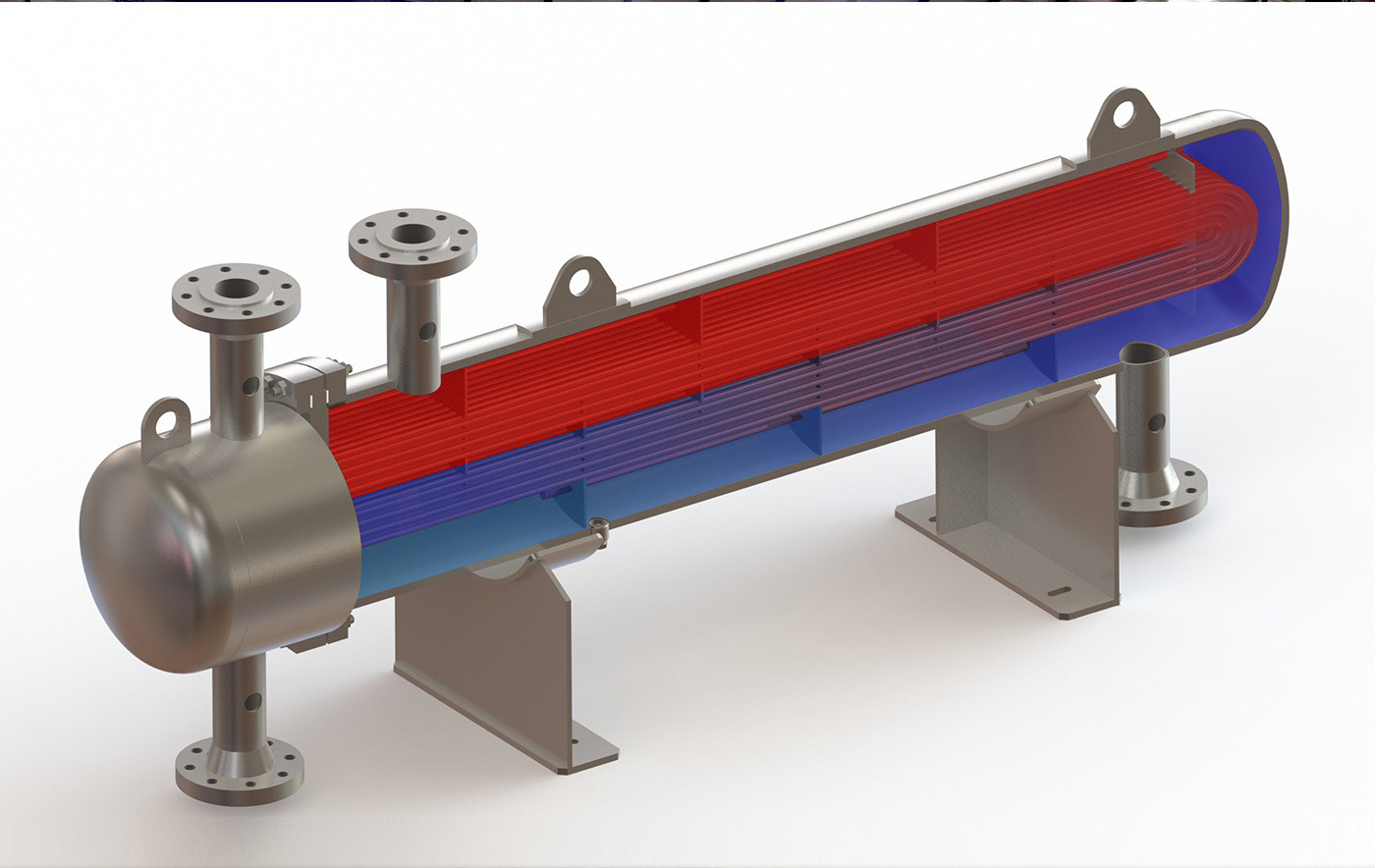

Shell & Tube Heat Exchanger

Thermal Design Engineering

Heat Exchanger Thermal Design

THERMAL ENGINEERING DESIGN EXPERTISE

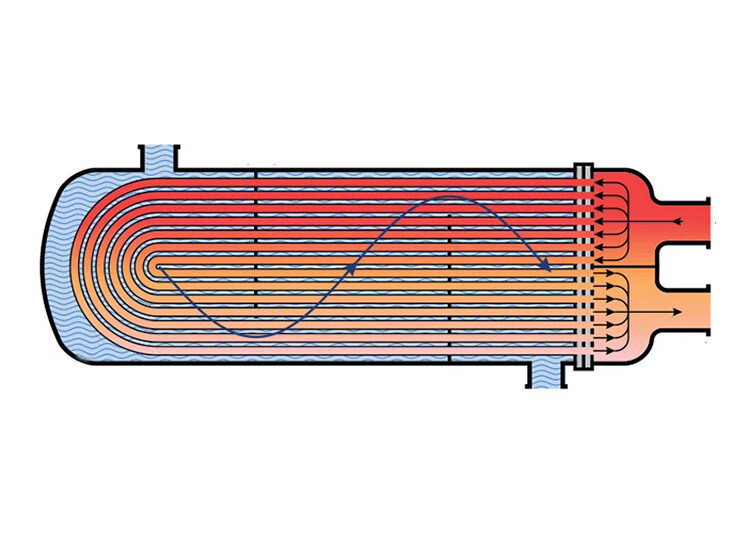

Our in-house thermal design engineers perform precise heat exchanger thermal design, analysis and optimization to ensure efficient thermal energy transfer and optimal performance of your units.

With expertise in fluid dynamics, thermodynamics, and heat transfer principles our teams can advise on materials selection and heat exchanger configurations best suited for your specific application and operating conditions.

By performing detailed calculations to determine optimal heat transfer coefficients, pressure drops, and temperature profiles, our teams ensure your heat exchanger meets performance specifications while maintaining dependable, efficient operation.

Heat exchangers designed by Metalforms, are guaranteed to maximize thermal efficiency with minimal vibrations, based on customer specified operating conditions for cost-effective—and reliable—operation to reduce downtime and maximize production

|

|

|

REQUEST A QUOTE

Our 24-7 teams can help—fast!

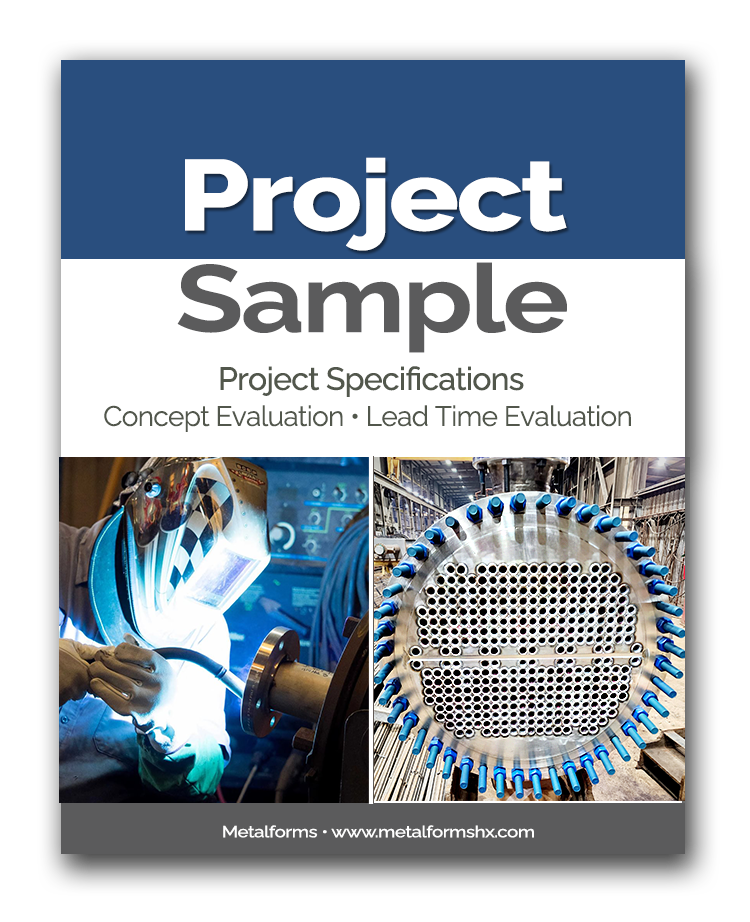

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

HEAT EXCHANGERS EXPERTISE

-

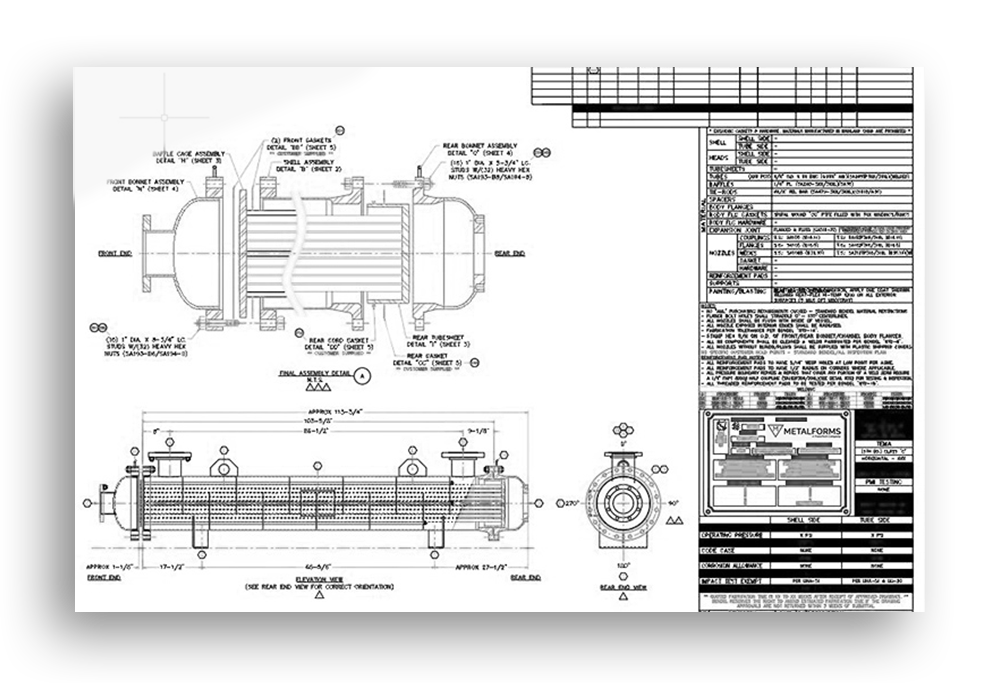

Thermal Design Software

All Metalforms thermal evaluations are performed by our in-house designers utilizing the latest version of Heat Transfer Research Institute’s Xist Exchanger Suite (HTRI) to perform thermal and vibration analysis.

Optimum sizing is determined based on customer specified tube side and shell side process conditions, stream compositions, physical space constraints, and piping limitations.

-

Design StandardsThroughout the heat exchanger design process, the Tubular Exchanger Manufacturing Association and American Petroleum Institute standards are strictly applied—in conjunction with customer design specifications.

Tubular Exchanger Manufacturing Association (TEMA) and American Petroleum Institute (API) 660 standards are applied in all designs. -

Applications

We provide shell and tube heat exchangers tailored to meet our customers’ diverse needs and facilitating efficient heat transfer, precise temperature control, and enhanced process performance across a range of applications, including:

• Cooling water systems

• Distillation and gas treating units

• Fuel gas conditioning systems

• Heat recovery systems

• Heat treatment systems

• Heat/oil transfer systems• Lube oil systems

• Power generation systems

• Product storage systems

• Selective catalytic reduction (SCR) units

• Steam systems

• Tank heating systems

• More

-

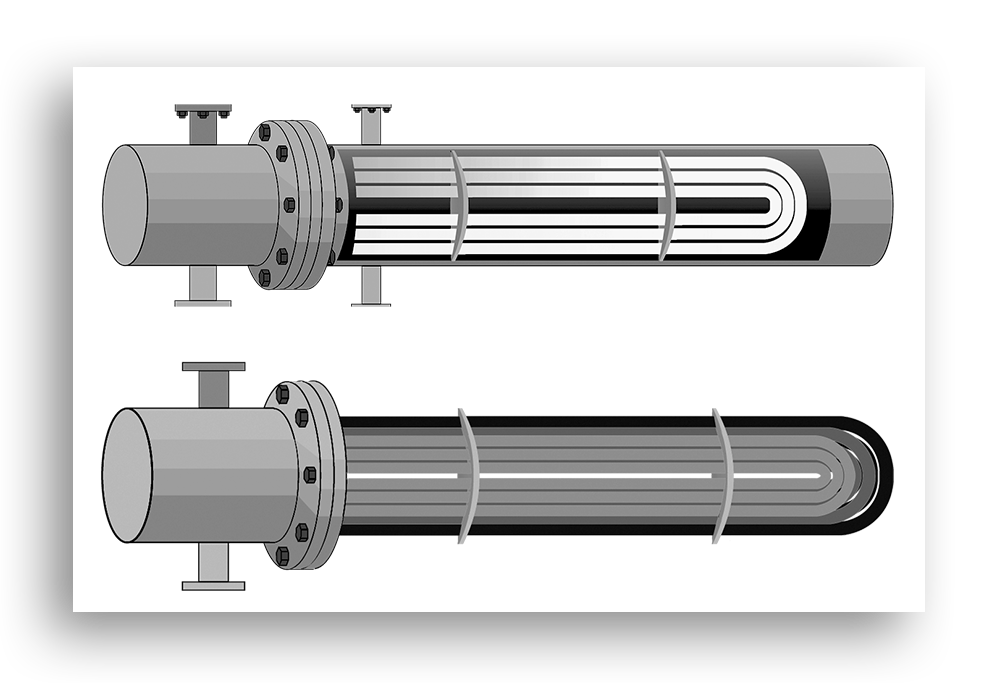

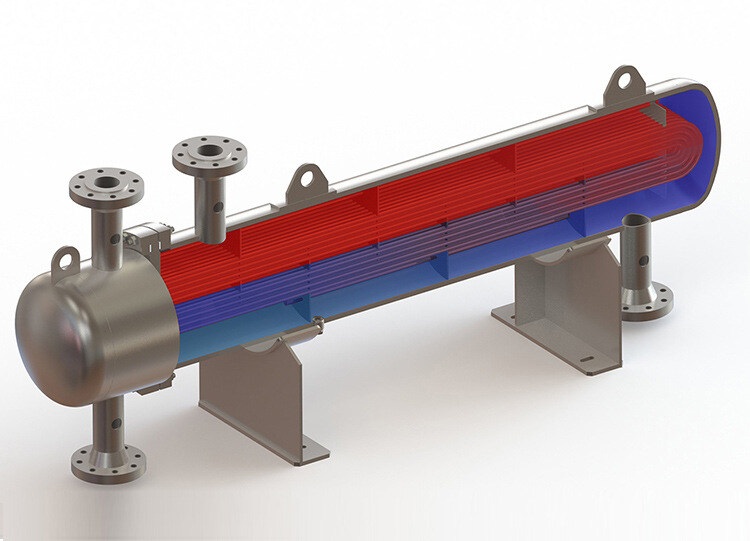

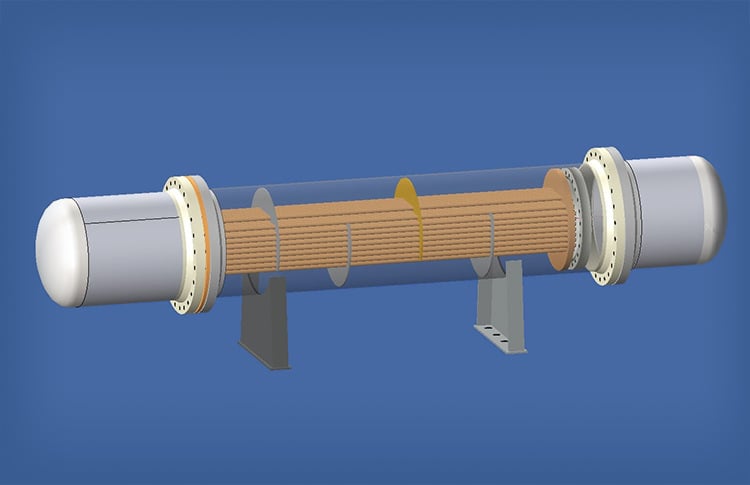

Heat Exchanger ConfigurationsWe manufacture an extensive variety of shell & tube heat exchanger configurations with options and characteristics to serve virtually any purpose, including the following:

• Double-Pipe• Floating & Fixed Head Options• Multitube• Parallel-Flow, Counter-Flow• Regenerative & Non-regenerative Configurations• Single & Double Tubesheet• Single Pass, Multi Pass• Standalone Units- U-tube

- Hairpin

- Parallel Units

- Expansion Joints

- Insulation Jackets

- Lined & Unlined Flanges

- With & Without Phase Change

-

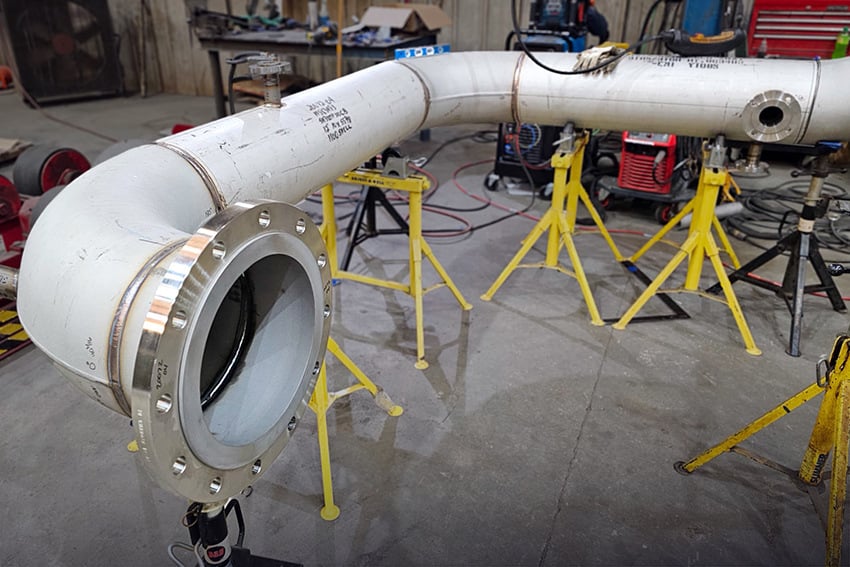

Example Projects

Our heat exchangers are meticulously designed to optimize thermal efficiency and reliability and ensure seamless integration—and superior performance—within your operations.

Example heat exchanger designs include:• Chillers / coolers

• Condensers

• Evaporators

• Fuel heaters

• Gas cooling

• Heaters

• Intercoolers

• Kettle reboilers• Preheaters

• Re-boilers

• Steam generators

• Super heaters

• Vaporizers

• Vacuum condensers

-

Certifications

Metalforms is committed to designing and fabricating the highest quality shell and tube heat exchangers to individual customer specifications and the following industry standards:

• TEMA Class R, C & B

• ASME U, U2, U3, and S Certifications

• NBIC Certification

• API 660

• Licensed fabricator of Phillips Petroleum

Rod Baffle Bundles

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only