HEAT EXCHANGER SERVICES

Comprehensive, End-to-End

Heat Exchanger Solutions & Services

Heat Exchanger Solutions Specialist

ONE-STOP HEAT EXCHANGER SOLUTIONS

Metalforms is a full-service design, fabrication, testing, maintenance, and repair facility that provides 24-7 support to all its clients, all 'in-house', with one-source quality assurance—one point of contact, one invoice.

Metalforms has specialized in the fabrication and repair of shell and tube heat exchangers since 1968, making us your ideal partner for all your heat exchanger needs—from new unit fabrication to repair, upgrades, maintenance, components, parts, re-rating, and other services—applying our decades of experience to every project

We are committed to delivering products that help our customers reduce and avoid downtime, improve quality, conserve resources, and foster sustainability to maximize production, reduce costs, and accelerate time-to-market supporting increased ROI—and enhancing competitive advantage for our customers.

|

|

|

SPECIALIZED SERVICES SHOPS

Heat Exchanger

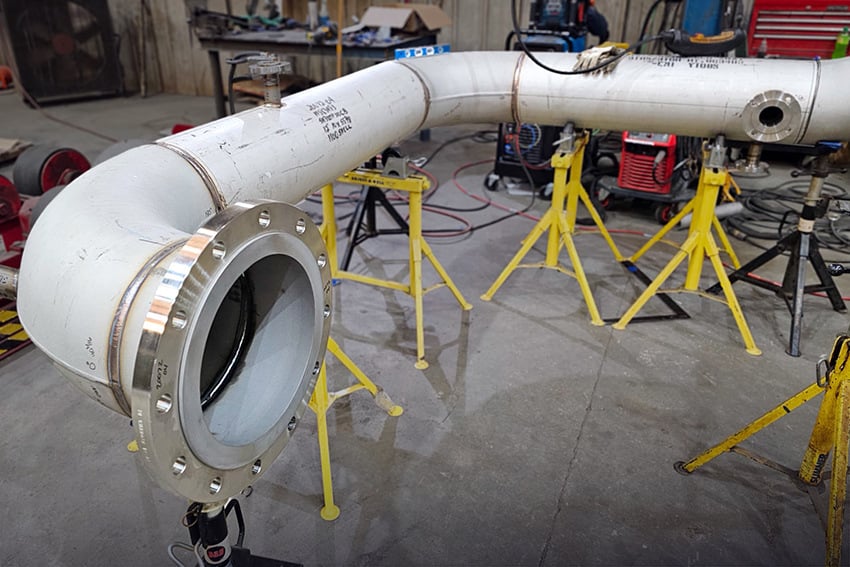

Fabrication Services

Metalforms is an industry leader in the design and fabrication of shell & tube heat exchangers for midstream oil & gas, refining, petrochemical, specialty chemical, and other process industries.

With 24/7 fabrication teams—and parallel, multi-track, project execution capabilities—we support all your project project needs—from greenfield projects to plant turnarounds, overhauls, debottlenecking, modifications, and upgrades—as well as urgent, emergency heat exchanger replacement.

Heat Exchanger

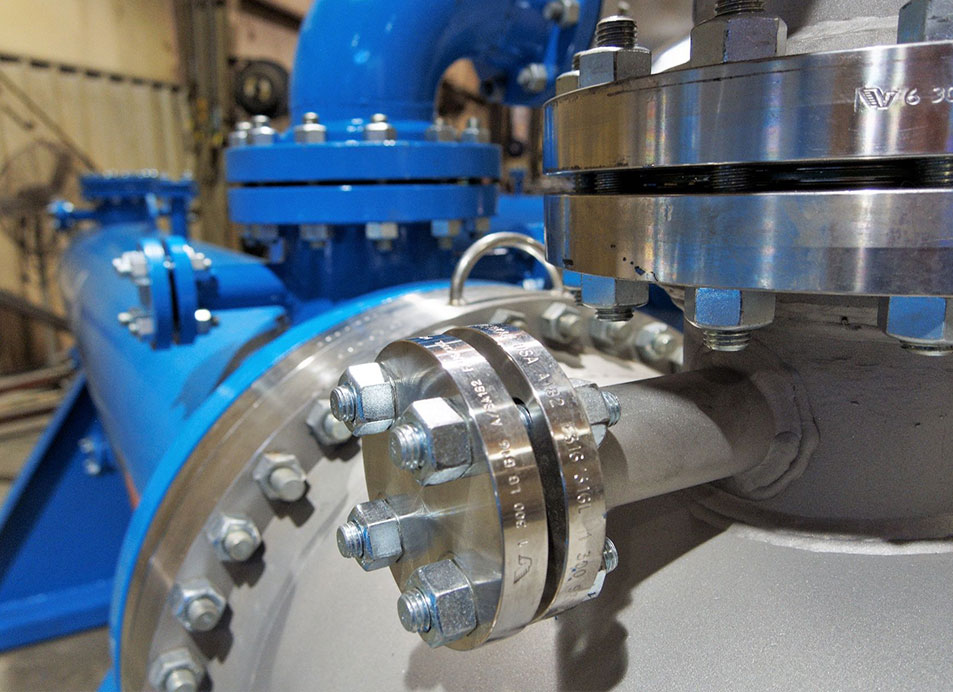

Machining & Drilling

Our specialized contract drilling and CNC machining services let our customers enjoy all the benefits of our superior tools and quality for both routine—and emergency—fabricated parts and components for shell & tube heat exchangers and ASME pressure vessels.

With 24-7 teams and extensive shop capacity, Metalforms is your ideal partner to help prevent and reduce downtime for all your planned turnarounds—and unplanned outages.

Full Service Heat Exchanger

Tube Bundle Fabrication

Our Bundle Shop produces the highest quality shell & tube heat exchanger tube bundles and air cooler (ACHEs) tube bundles for newly fabricated heat exchangers, replacement, or repair.

In addition to the assembly of new tube bundle units, the Shop performs expert bundle repairs—including complete strip and retube services for both TEMA type heat exchangers and ACHEs.

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

HEAT EXCHANGERS EXPERTISE

-

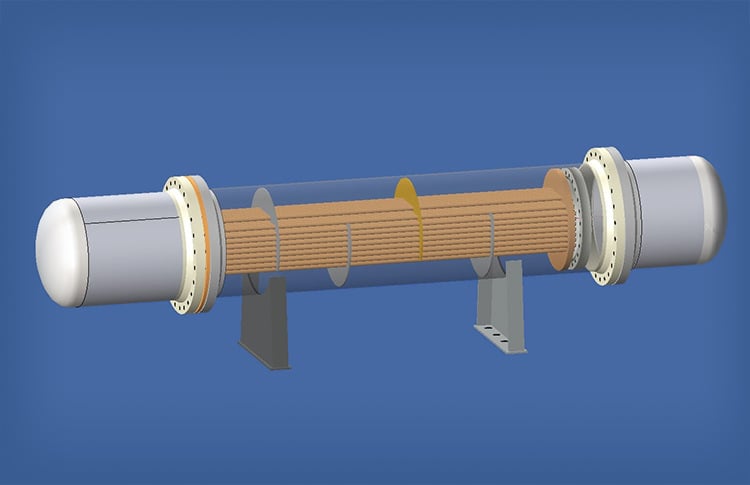

New Heat Exchanger FabricationWe manufacture a broad range of shell & tube heat exchangers for customers in midstream oil and gas, refining, petrochemical, and chemical industries and other process industries—with available options and configurations to serve virtually any purpose. All our heat exchangers are built to ASME, TEMA, and API standards as applicable in addition to customer specifications. Example options include:

• Double-Pipe• Floating & Fixed Head Options• Multitube• Parallel-Flow, Counter-Flow• Regenerative & Non-regenerative Configurations• Single & Double Tubesheet• Single Pass, Multi Pass• Standalone Units- U-tube

- Parallel Units

- Expansion Joints

- Insulation Jackets

- Lined & Unlined Flanges

- With & Without Phase Change

-

Strip & Retube

Our strip & retube capabilities and expertise is available for all TEMA types of shell and tube heat exchangers as well as fin-fan type air cooled heat exchangers (ACHEs - also called air coolers.)

We have the unique ability to handle multiple strip and retube jobs simultaneously—and with our ability to perform work around the clock, 24/7, we can meet your most demanding project needs!

-

RepairsWhen your heat exchangers arrive at our shop for repair, our expert teams rapidly inspect and diagnose your units for both common and highly complex issues. Prior to work commencing, all needed repairs—and options—are discussed with the customer. Common repairs include:

- Gasket surface repair

- Weld repairs

- Weld build-up & re-machining

- Replacement components

- Repairs to shell & channel

components - Coating & paint application

The most common types of weld repairs we perform are weld build-up repair of eroded or corroded areas, removal of cracks and re-weld of those defects, and weld build-up for reclaiming gasket surfaces. Any defects we find are removed by following the ASME Section IX qualified weld procedures.

We work closely with our customers, to ensure their specific needs are met.

-

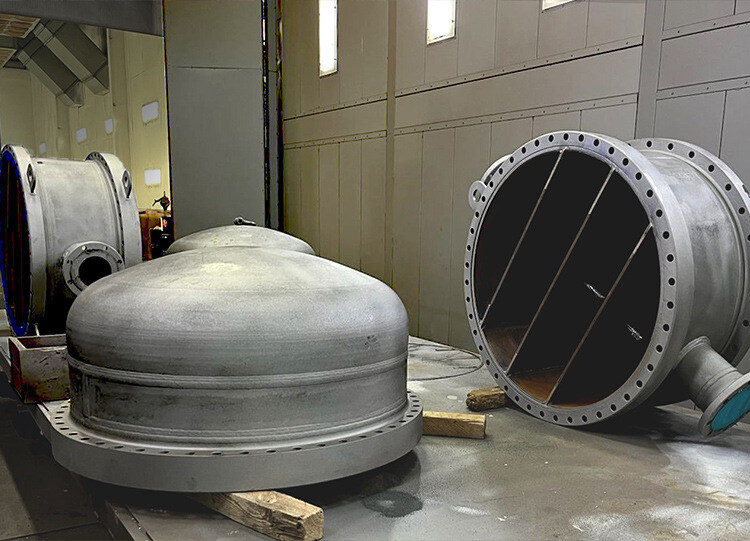

Replacement PartsMetalforms manufactures replacement parts for both standard and emergency needs. With 24-7 engineering and fabrication teams, we can assist with your most urgent shell & tube heat exchanger parts and component needs including:

• Replacement bundles including u-tube, straight tube, & hairpin configurations

• Fixed & floating heads

• Replacement shells

• Bundle/shell combinations

• Replacement channels

•. Gaskets• Replacement channel covers

• Baffles

• Nozzles

• Insulation

• Expansion joints

• Various other miscellaneous parts

Learn more about our shell & tube heat exchanger components & parts services here.

-

Re-Rate & ModificationWe can re-rate, adjust, upgrade, or reconfigure your current shell and tube heat exchanger or ASME pressure vessel to suit new operatong conditions or to suit new applications at your plant.

Rerating:

After a thorough evaluation of your unit, we'll discuss any needed modifications with you prior to beginning any work. If your unit already meets new requirements and/or once updates have been made, we'll provide all necessary documentation—to confirm the existing design will safely and efficiently perform to the new specifications, as required by owners and regulators alike.

Modifications

Whether or not re-rating is required, we can assist with virtually any shell & tube heat exchanger or ASME pressure vessel repair and/or alteration including design, configuration, options/features, or materials of construction.

All modified units will meet all applicable ASME, NBIC, TEMA, and API codes and standards.

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only