24-7 HEAT EXCHANGER

REPAIR SERVICES

Shell & Tube Heat Exchanger Inspection,

Repair, & Modification

Heat Exchanger Repair Specialist

24-7 SHELL & TUBE HEAT EXCHANGER REPAIR

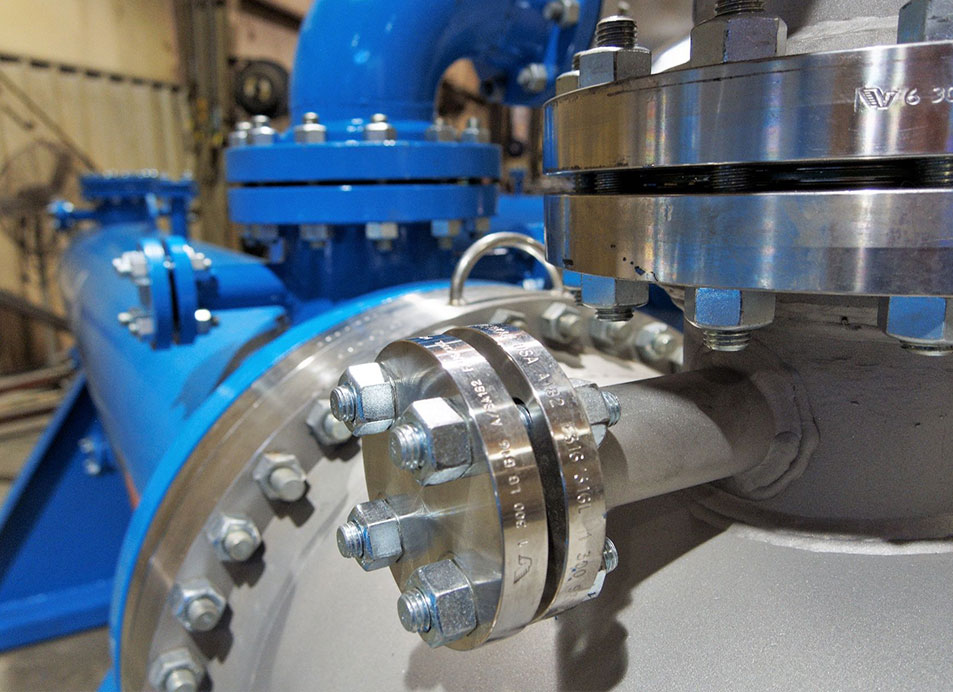

Backed by over five decades of experience, Metalforms delivers the most comprehensive shell & tube heat exchanger repair services you’ll find—all in one place. One point of contact. One invoice.

Whether you need a single part or a complex unit repair, we can assist with every need—from gasket surface repair, weld repairs, and re-machining to component replacement, re-tubing, material upgrades, re-rating, and more.

Rapid Turnaround on Repairs

We understand your heat exchangers are critical process components—and when urgent repairs are needed, speed counts. With 24-7 service teams, and parallel track, multi-project execution capabilities, we have the expertise, capabilities, and skills needed to handle your heat transfer equipment repairs quickly and correctly, to get your plant back online—fast.

|

|

|

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

HEAT EXCHANGER REPAIRS EXPERTISE

-

Inspection & Troubleshooting

With in-house mechanical and thermal engineering teams and full-scope NDE services, our seasoned heat exchanger professionals have the capabilities and tools to provide a comprehensive assessment of your shell and tube heat exchanger—and identify any issues that might interfere with the integrity, efficiency, and safety of the unit such as:

• Pressure drop issues

• Erosion

• Corrosion

• Vibration wear & damage

• Differential thermal expansion issues

• Temperature cross / pinch point issues

• Mechanical issues• Tube blockage

• Fouling

• Leaks

• Flow rates

• Tube pitch issues

• Gasket failure

• More

-

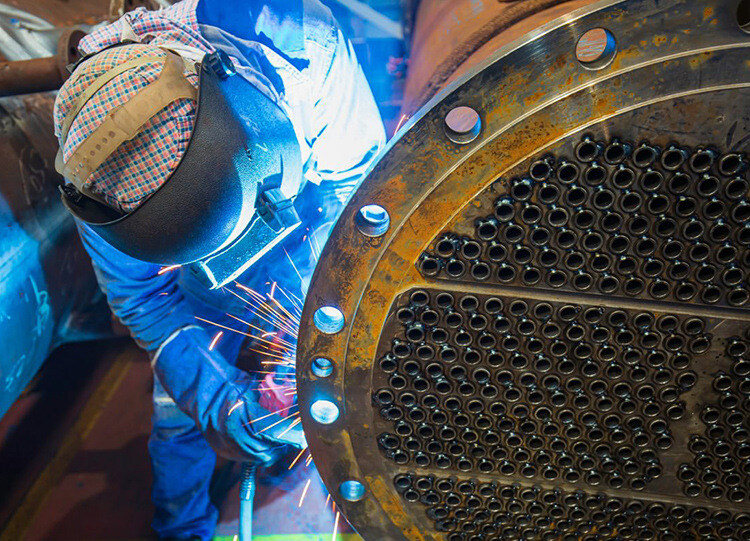

Common Repairs We PerformYou can rely on Metalforms' expert teams to rapidly diagnose and repair your heat exchangers for both common and highly complex issues, including:

- Strip & Retube

- Gasket surface repair

- Weld repairs

- Weld build-up & re-machining

- Replacement parts & components

- Pass partition plate replacement (partial and full)

- Repairs to shell & channel

components - Coating & paint application

The most common types of weld repairs we perform are weld build-up repair of eroded or corroded areas, removal of cracks and re-weld of those defects, and weld build-up for reclaiming gasket surfaces. Any defects we find are removed by following the ASME Section IX qualified weld procedures.

We work closely with our customers, to ensure their specific needs are met.

-

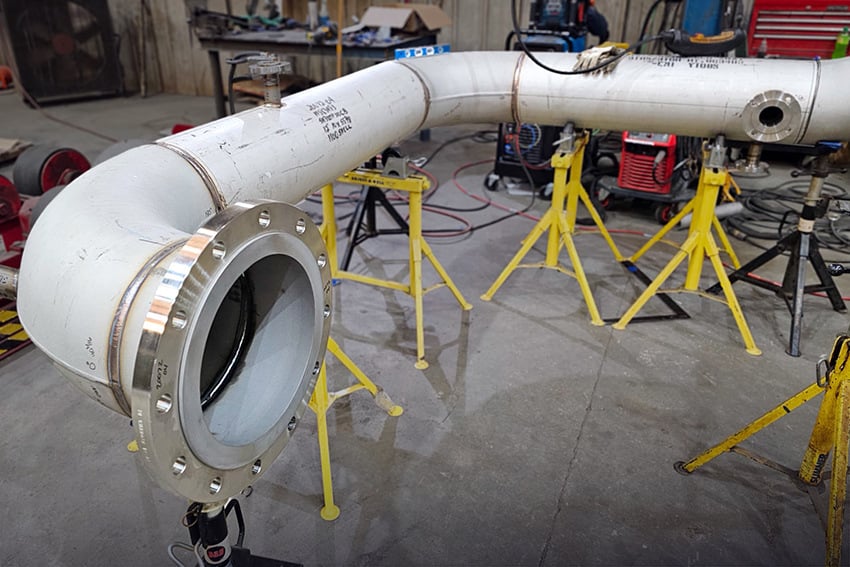

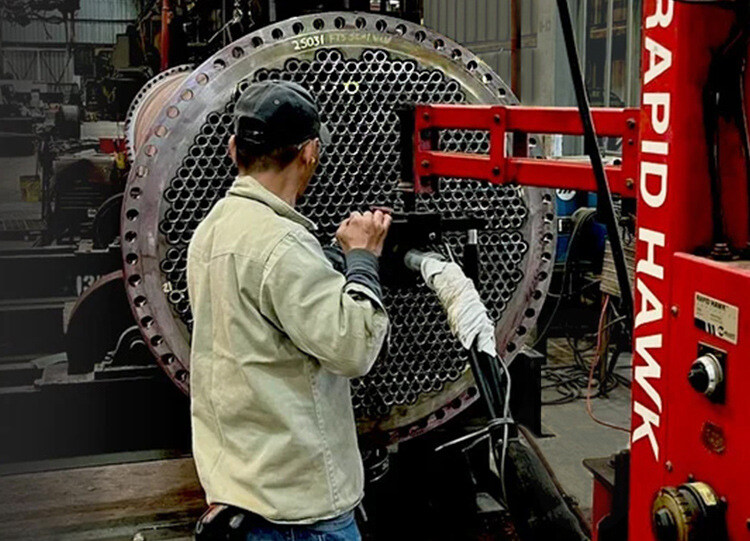

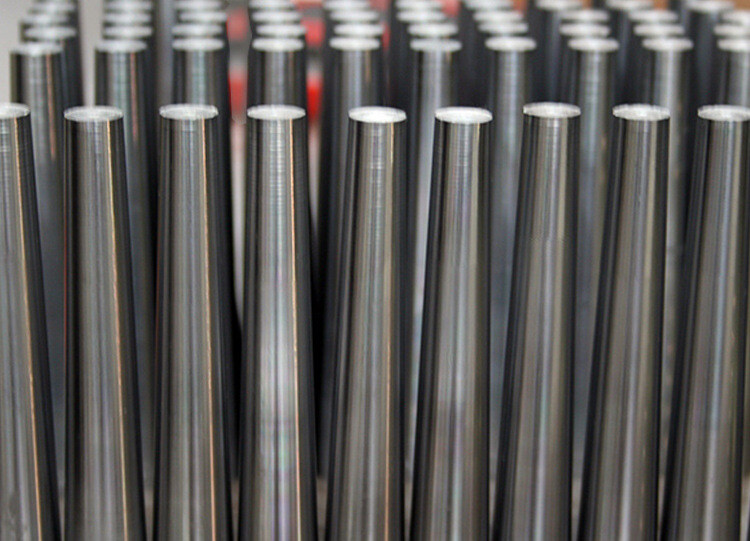

Strip & Retube

We offer strip & retube services for all TEMA types of shell and tube heat exchangers as well as fin-fan type air cooled heat exchangers (ACHEs) - also referred to as air coolers.

With the ability to perform multiple, parallel workflows, Metalforms has the distinct advantage of offering multiple, simultaneous strip and retube projects. Coupled with our ability to perform work around the clock, 24/7, we can meet your most demanding project needs!

-

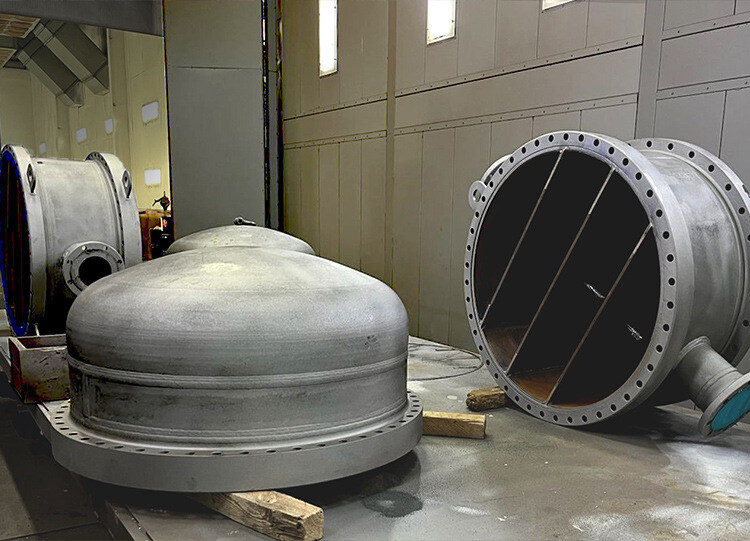

Component & Part ReplacementMetalforms manufactures replacement parts to both standard and emergency schedules. With 24-7 engineering and fabrication teams, we can assist with your most urgent shell & tube heat exchanger parts and component needs including:

• Replacement bundles including u-tube, straight tube, & hairpin configurations

• Fixed & floating heads

• Replacement shells

• Bundle/shell combinations

• Replacement channels

•. Gaskets• Replacement channel covers

• Baffles

• Nozzles

• Insulation

• Expansion joints

• Various other miscellaneous parts

Learn more about our shell & tube heat exchanger components & parts services here.

-

Gasket Surface RepairOur QC professionals inspect shell & tube heat exchanger gasket surfaces using sandblasting, which improves visibility of the base metals—and which is typically not possible with the standard inspection methods available at the plant.

Should any defects be detected, we review all findings with our customers to discuss options, prior to commencing any repairs.

Depending upon the nature of the defect found, our repair professionals can perform weld repairs using ASME Section IX qualified weld procedures and re-machine gasket surfaces to meet original specifications.

If damage is severe and repair is not possible—or simply not cost effective—we may recommend gasket replacement.

-

Tube Re-rolling

Proper tube expansion is critical to maintaining efficient heat transfer and structural integrity in heat exchanger operations.

We have both the equipment and expertise to rapidly re-expand existing tube-to-tubesheet joints to repair seal integrity prior to installation / re-installation of tube bundles.

Automated processes expedite repairs while promoting consistent, reliable outcomes.

-

Tube Plugs

Metalforms manufactures shell & tube heat exchanger tube plugs for field maintenance and repair purposes, to seal off or block individual tubes that may be leaking, damaged, or in need of isolation due to operational changes—or as a precautionary measure during plant shutdowns and turnarounds to maintain system integrity and safety.

We maintain a stock of over 50,000 standard tube plugs in a variety of materials at all times, to support rapid response for all your tube plug needs. Tube plugs are available for immediate shipment, with a minimum order of 25 required.

-

In-house NDE

Our seasoned teams utilize a variety of non-destructive examination (NDE) methods to inspect both newly fabricated heat exchangers and other equipment as well as to diagnose issues with in-service and used equipment to ensure optimal quality efficiency, reliability, and safety, including:

● Radiography Liquid Penetrant

● Magnetic Particle

● Brinell Hardness

● PMI (XRF Analyzer)

● Hydro Testing

● In-house PWHT Oven

● 8’-0” X 8’0” X 20’-0”

● In-house Local Stress Relieving

● Detailed Inspection of Existing Units

-

CertificationsMetalforms is authorized by ASME to apply certification mark for U, S, and PP; and authorized by the National Board Inspection Code to apply R, NB and H stamps.

Whether you need a single part or a complete shell and tube heat exchanger, all products confirm to the following industry standards: ASME Boiler and Pressure Vessel Code Section VIII Division I, TEMA, National Board, API 660, 661, 605, and NACE where applicable—in addition to individual customer specifications.

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only

ACHIEVE PEAK PLANT PERFORMANCE

SPECIALIZED SERVICES SHOPS

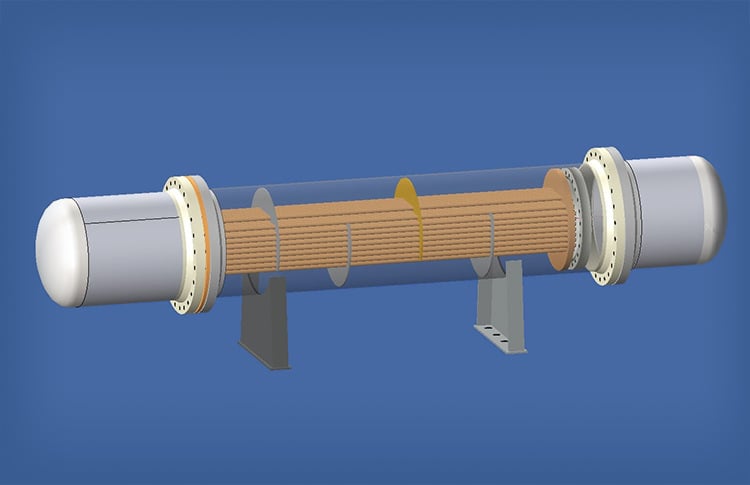

Heat Exchanger

Fabrication Services

Metalforms is an industry leader in the design and fabrication of shell & tube heat exchangers for midstream oil & gas, refining, petrochemical, specialty chemical, and other process industries.

With 24/7 fabrication teams—and parallel, multi-track, project execution capabilities—we support all your project project needs—from greenfield projects to plant turnarounds, overhauls, debottlenecking, modifications, and upgrades—as well as urgent, emergency heat exchanger replacement.

Heat Exchanger

Machining & Drilling

Our specialized contract drilling and CNC machining services let our customers enjoy all the benefits of our superior tools and quality for both routine—and emergency—fabricated parts and components for shell & tube heat exchangers and ASME pressure vessels.

With 24-7 teams and extensive shop capacity, Metalforms is your ideal partner to help prevent and reduce downtime for all your planned turnarounds—and unplanned outages.

Full Service Heat Exchanger

Tube Bundle Fabrication

Our Bundle Shop produces the highest quality shell & tube heat exchanger tube bundles and air cooler (ACHEs) tube bundles for newly fabricated heat exchangers, replacement, or repair.

In addition to the assembly of new tube bundle units, the Shop performs expert bundle repairs—including complete strip and retube services for both TEMA type heat exchangers and ACHEs.