ENGINEERING RE-RATE

& MODIFICATION

Shell & Tube Heat Exchanger & ASME Pressure Vessel Re-Rating & R-Stamp Modification

Heat Exchanger Solutions Specialist

EXPERT ENGINEERING RE-RATE & MODIFICATION

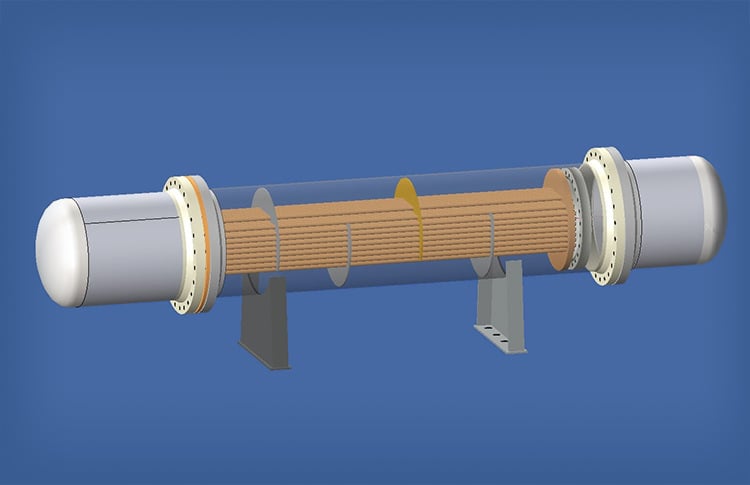

We can re-rate, adjust, upgrade, or reconfigure your current shell and tube heat exchanger or ASME pressure vessel to suit new conditions or applications—often at significantly lower cost than investing in a newly fabricated unit.

ENGINEERING RE-RATE

In some cases, heat exchangers and pressure vessels can be re-rated without requiring any modification. Our expert engineering teams can deliver a thorough evaluation—and all necessary documentation—to confirm the existing design will safely and efficiently perform to the new specifications, as required by owners and regulators alike.

ASME U-STAMP REPAIR & R-STAMP MODIFICATIONS

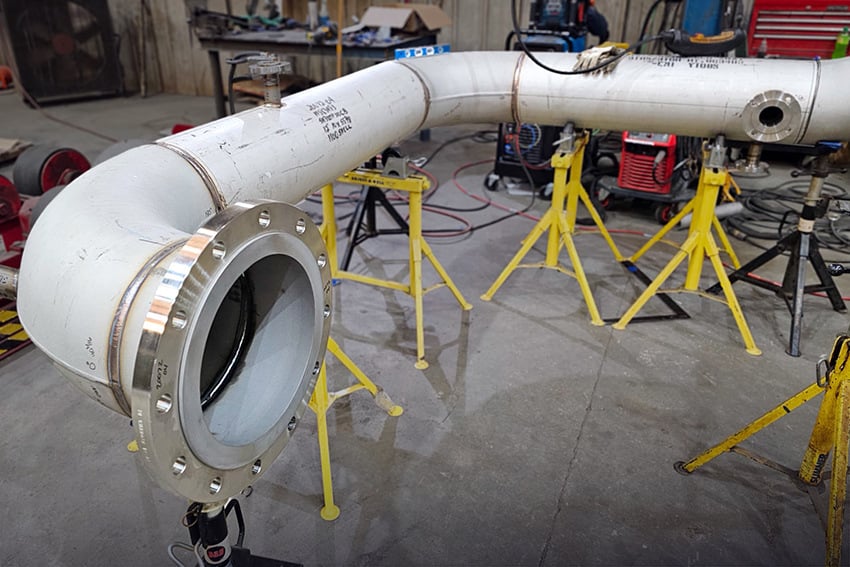

Whether or not re-rating is required, we can assist with virtually any shell & tube heat exchanger or ASME pressure vessel repair and/or alteration including design, configuration, options/features, or materials of construction.

All modified units will meet all applicable ASME, NBIC, TEMA, and API codes and standards

|

|

|

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

RE-RATE & MODIFICATION

-

ApplicationsWe can re-rate, adjust, upgrade, or reconfigure your current shell and tube heat exchanger or ASME pressure vessel to suit new operating conditions or to suit new applications at your plant.

Rerating:

After a thorough evaluation of your unit, we'll discuss any needed modifications with you prior to beginning any work. If your unit already meets new requirements and/or once updates have been made, we'll provide all necessary documentation—to confirm the existing design will safely and efficiently perform to the new specifications, as required by owners and regulators alike.

Modifications

Whether or not re-rating is required, we can assist with virtually any shell & tube heat exchanger or ASME pressure vessel repair and/or alteration including design, configuration, options/features, or materials of construction.

All modified units will meet all applicable ASME, NBIC, TEMA, and API codes and standards.

-

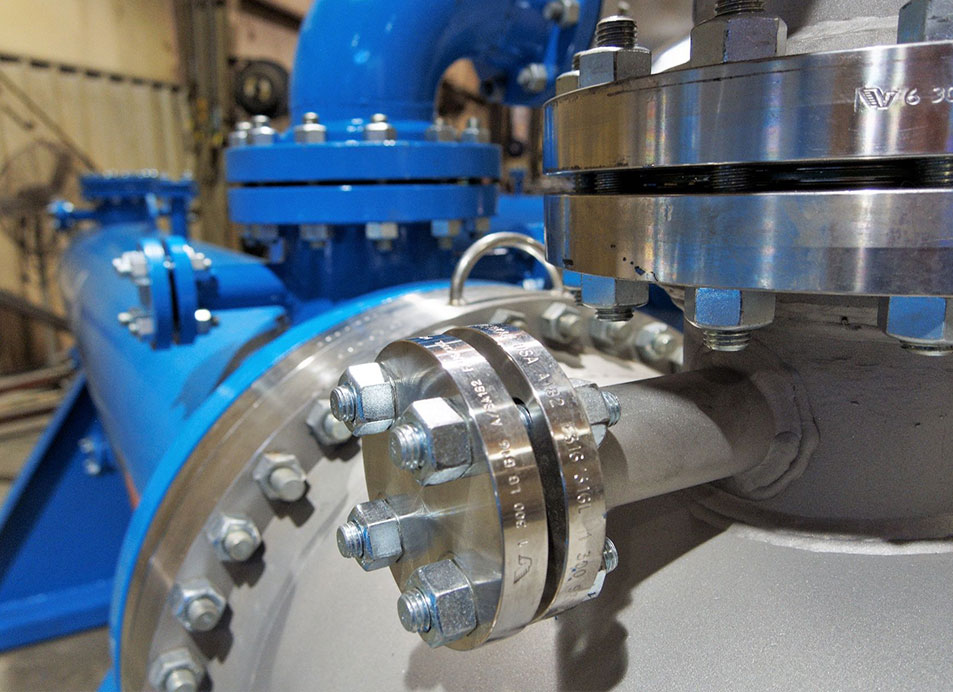

Shell & Tube Heat Exchanger ModificationWhether you need a simple tube bundle replacement, a complete shell modification, or an upgrade to enhance performance, we can help. From small-scale repairs to fully custom retrofits, we provide expert solutions designed to optimize your heat exchanger’s performance and reliability, including:

• Materials upgrades for performance, longevity

• Increasing or decreasing tube bundle tube length

• Addition of tube fins or other enhancements

• Fouling-resistant coatings

• Corrosion-resistant coatings

• Number of tube passes/updates

• Enhancing structural integrity of channels or end covers

• Shell thickness adjustments

• Gasket material upgrades

• Nozzle location changes

• Support structure enhancements

All changes are made in accordance with ASME, API, and TEMA standards and requirements.

-

ASME Pressure Vessel ModificationWhether you require a simple nozzle modification, heat exchanger replacement shell and/or tubes, reactor repair, or a complete, custom fabricated storage or process vessel for a specific application, we're here to help. We deliver timely, turnkey solutions including:

• National Board R Stamp modifications and new vessel fabrication

• ASME storage and process vessels, reactor vessels, heat exchangers, columns & towers, more

• All required inspections, testing and certifications

• AWS-certified welding

• Reconditioning and coating services

• Logistics coordination- loading, freight management and unloading on your site

-

Metallurgy

We utilize an extensive array of metallurgies to meet your specific application requirements, including:

• Carbon Steel

• Low Alloy Steel

• Austenitic Stainless Steel

• Ferritic Stainless Steel

• Duplex Stainless Steel

• Titanium

• Copper Nickel1 ¼

• Chrome• Hastelloy

• Inconel

• Monel

• Nickel

• Brass

• Explosive Bond Cladded Materials

-

Certifications

Metalforms is committed to designing, fabricating, repairing, upgrading, and/or re-rating shell and tube heat exchangers to achieve the highest quality standards and deliver to individual customer specifications, in addition to the following industry standards:

• TEMA Class R, C & B

• ASME U, U2, U3, and S Certifications

• NBIC Certification

• API 660

• Licensed fabricator of Phillips Petroleum

Rod Baffle Bundles

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only

ACHIEVE PEAK PLANT PERFORMANCE

SPECIALIZED SERVICES SHOPS

Heat Exchanger

Fabrication Services

Metalforms is an industry leader in the design and fabrication of shell & tube heat exchangers for midstream oil & gas, refining, petrochemical, specialty chemical, and other process industries.

With 24/7 fabrication teams—and parallel, multi-track, project execution capabilities—we support all your project project needs—from greenfield projects to plant turnarounds, overhauls, debottlenecking, modifications, and upgrades—as well as urgent, emergency heat exchanger replacement.

Heat Exchanger

Machining & Drilling

Our specialized contract drilling and CNC machining services let our customers enjoy all the benefits of our superior tools and quality for both routine—and emergency—fabricated parts and components for shell & tube heat exchangers and ASME pressure vessels.

With 24-7 teams and extensive shop capacity, Metalforms is your ideal partner to help prevent and reduce downtime for all your planned turnarounds—and unplanned outages.

Full Service Heat Exchanger

Tube Bundle Fabrication

Our Bundle Shop produces the highest quality shell & tube heat exchanger tube bundles and air cooler (ACHEs) tube bundles for newly fabricated heat exchangers, replacement, or repair.

In addition to the assembly of new tube bundle units, the Shop performs expert bundle repairs—including complete strip and retube services for both TEMA type heat exchangers and ACHEs.