ENGINEERING & DESIGN

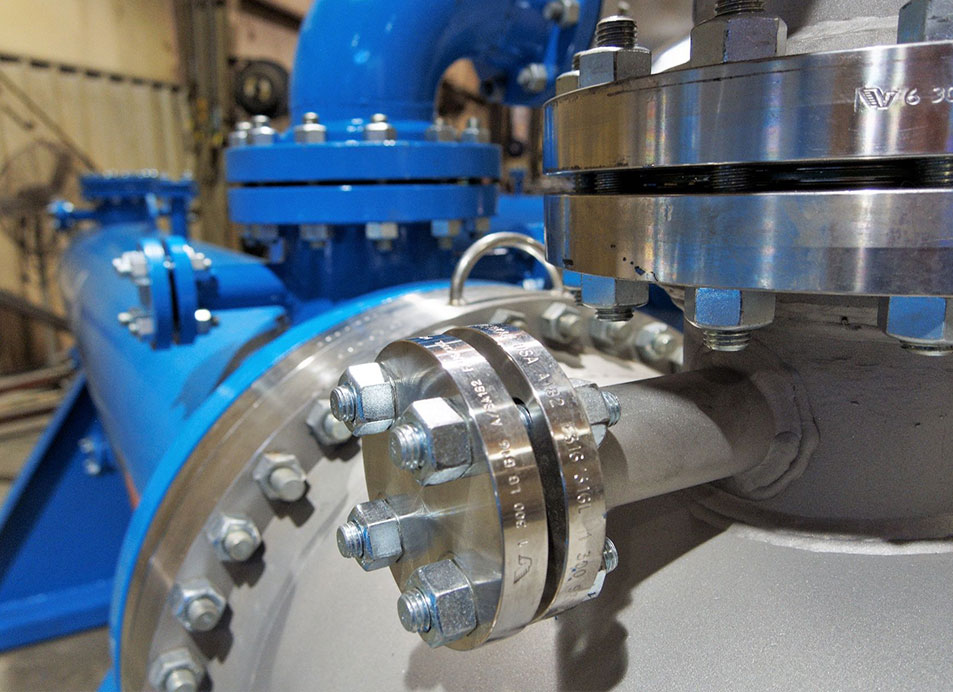

Heat Exchangers, ASME Pressure Vessels, Piping

& Equipment Engineering, Design, Drafting

Engineering, Design, & Drafting

ENGINEERING & DESIGN SPECIALISTS

Metalforms’ in-house design group includes highly qualified teams of engineers holding degrees in chemical, mechanical, and industrial engineering—as well as a team of expert CAD, HTRI, cross/pinch, and WRC draftsmen.

Our integrated engineering & design teams work in close collaboration to meticulously design each project—ensuring all industry standards and customer specifications are met.

If you are in need of a new design, re-design of an under-performing unit, or engineering re-rate for an existing unit, we have the expertise to deliver the solution you need—all under one roof!

Our engineering & design professionals work in close collaboration with our fabrication teams to serve both routine and emergency needs.

CONTACT US:

Call us today to speak with one of our engineering & design specialists at: +1 409-842-1626 or click to contact us below:

SPECIALIZED SERVICES SHOPS

Thermal Design

Engineering

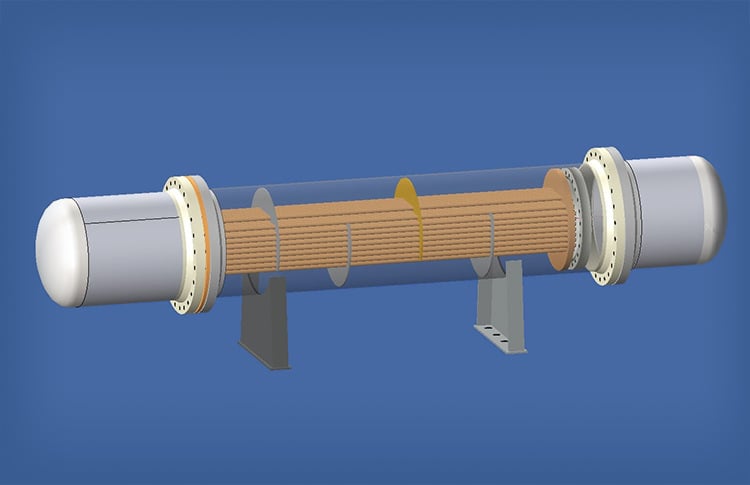

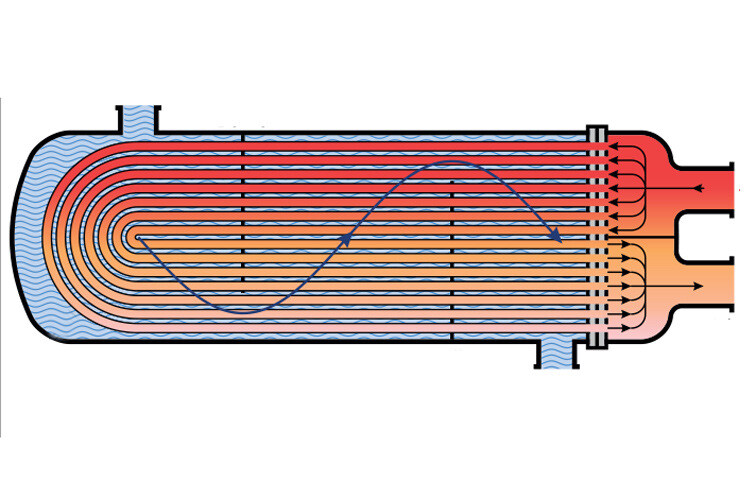

Our thermal design engineers perform precise thermal design, analysis and optimization to ensure efficient thermal energy transfer and optimal performance of your heat exchangers.

With expertise in fluid dynamics, thermodynamics, and heat transfer principles, our skilled practitioners can advise on materials selection and heat exchanger configurations best suited for your specific operating conditions—to ensure efficient thermal energy transfer and optimal performance of your units.

Our thermal design team also ensures the integrity and performance of pressure vessels and other equipment in applications where temperature changes or thermal gradients can affect their operational efficiency, reliability—and uptime.

Mechanical Design

& Engineering

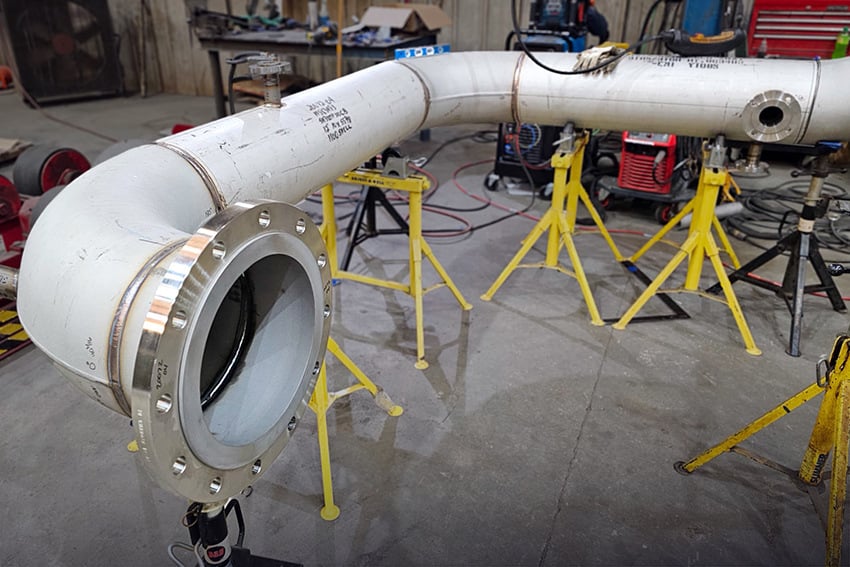

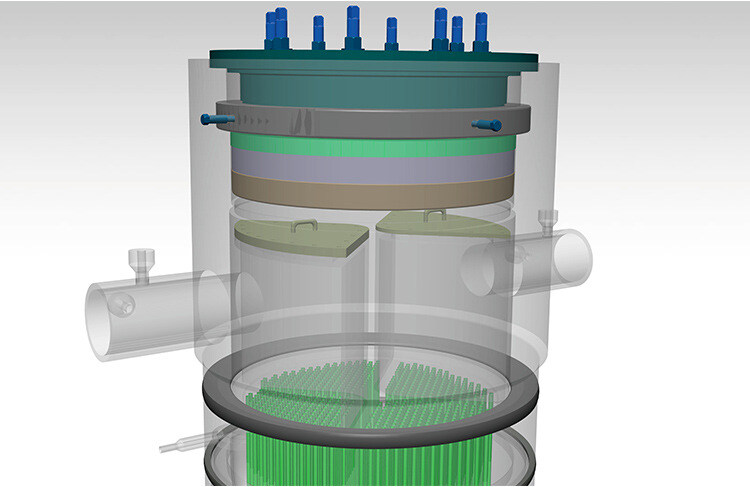

Our seasoned in-house mechanical design engineers perform expert design of all heat exchanger, pressure vessel, and equipment structural components such as shells, tubes, baffles, and headers to ensure they can withstand the mechanical stresses, pressures, and environmental conditions they will encounter during operation.

At Metalforms, we are committed to ensuring the structural integrity, durability, efficiency, and safety of your equipment for your process, to support optimal performance and reliability—and maximum uptime.

CAD/Drafting

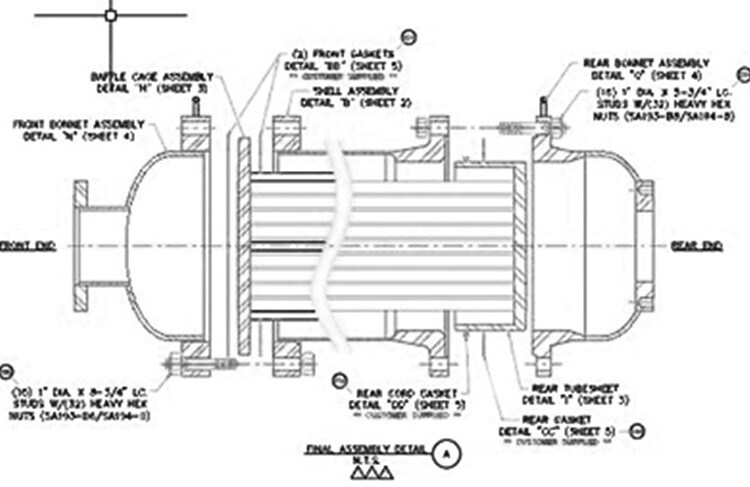

Our CAD department consists of a versatile team of drafters with degrees in Computer-Aided Design and Mechanical Engineering. All our drafters are cross-trained in our Quality Control department—which gives them an edge in understanding and applying non-destructive examination (NDE) requirements to all your heat exchanger, vessel, equipment, and piping projects.

Our process—including the close integration of all our engineering and fabrication teams—ensures alignment with design standards and project specifications, and that your heat exchanger and other equipment is constructed to precise specifications for optimal performance, reliability, and uptime.

FREE Specialized Services Overview

Receive a Detailed Overview of All Our Services

- A Complete Services Overview

- Capabilities & Solutions

- Sample Projects

- Locations & Contacts

- More

HEAT EXCHANGER SERVICES

FREE Seminar: Heat Exchanger

Design & Fabrication Principals

Join us in Beaumont, Texas!

This on-site course for new engineers and others combines classroom discussion with a tour of our active shop to provide a complete, understanding of the shell & tube heat exchanger specification, design and fabrication process!

Open to qualified owners/operators and EPC participants only